Dependability, timeliness, quality, and social responsibility define STARPOL II’s core values.

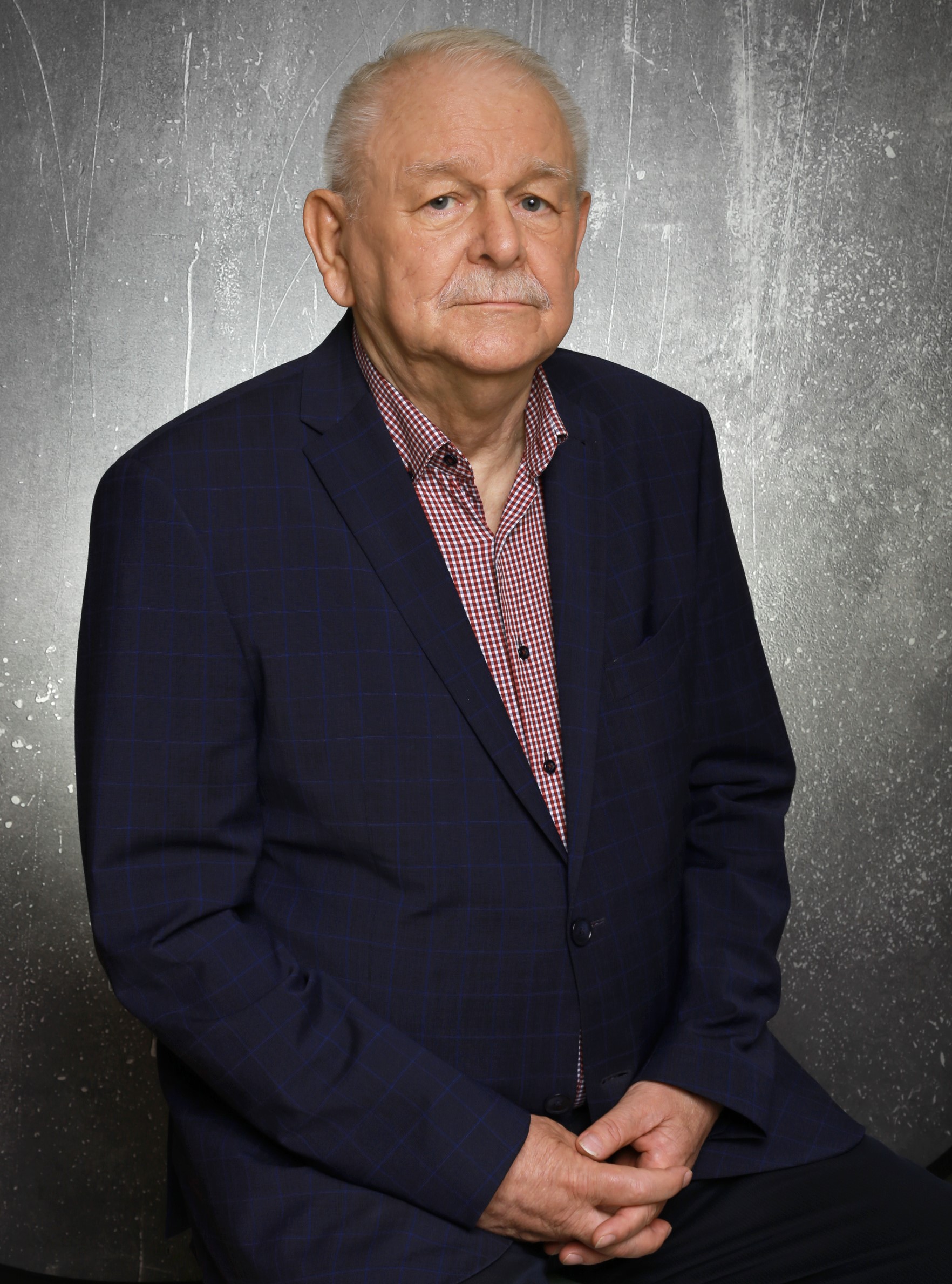

STARPOL was established in 1991 based on private capital. The founder and main owner is Edward Płusa. The company’s facilities are located in Starachowice within the Special Economic Zone, in three production halls covering around 10,000 m², where wiring harnesses are assembled and metal manufacturing is conducted.

The company offers high-quality products and services, confirmed by the Quality Management System Certificate DIN EN ISO 9001:2015 and the Environmental Certificate DIN EN ISO 14001:2015. In recent years, we have strengthened our commitment to sustainable growth and social responsibility in various areas.

Community Initiatives

The company actively and regularly supports local cultural institutions – the Starachowice Cultural Park, sports teams (Starachowice Kyokushin Karate Club Senshi, Barakuda Swimming Club, STAR Football Club), as well as associations (Friends of Starachowice Society, University of the Third Age).

Starpol also has a patronage class at Vocational School Complex No. 3 in Starachowice, specializing in machine tool operation. Students from these classes complete apprenticeships at our company based on an employment contract – as juvenile workers – and can expect employment after completing their education in the profession.

Environment

In terms of environmental protection, the machinery park is continuously modernized to consume significantly less energy. The entire factory’s lighting has been replaced with energy-efficient solutions, and air curtains have been installed in production hall gates to reduce heat loss during the heating season.

At the Metal Plant, special extraction systems with filters have been installed above welding stations, contributing to improved air quality. To meet increasing customer demands, expand the offer, and optimize work time at the Metal Plant, welding robots and a new laser have recently been purchased. A photovoltaic installation has been set up on the company’s premises, covering approximately 40% of the electricity demand.

Moreover, the agreement with the energy supplier ensures that all the electricity provided comes exclusively from renewable energy sources. Additionally, part of the company’s fleet has been replaced with electric vehicles, which are charged on-site.

The company places great emphasis on waste segregation, conducting regular employee training sessions. To improve waste sorting and minimize waste production, a specialized machine (grinder) has been purchased, enabling nearly 100% recycling of PVC waste generated during the production of plastic components. Furthermore, Starpol has digitized administrative processes by implementing an electronic document circulation system, which has significantly reduced paper consumption. Drinking water for office needs is purchased exclusively in glass bottles. Clearly, the company prioritizes continuous growth through investments in new technologies, while its environmentally focused initiatives contribute to strengthening corporate social responsibility.

We will help your business

Why choose us?

Starpol is a company with a rich history and many years of experience in the industry. It was established in 1991 and has been constantly developing since then, adapting its offer to changing market trends and growing customer expectations.

The pursuit of continuous development and openness to new solutions make Starpol a solid and trustworthy business partner that combines tradition with modernity, while ensuring the highest production standards.

1991

Starting a business

1992

Establishing cooperation with STAR S.A.

1994

Obtaining the status of a Sheltered Workshop

1994

Beginning of cooperation with Polar S.A.

2000

Start of production for Indesit S.A.

2002

Establishing cooperation with Whirlpool

2003

Start of production for New Holland (CNH) in Płock

2003

Establishing cooperation with MAN and establishing a new business line – a metal plant

2007

Change of company location – SSE Starachowice. Start of production for Saint-Gobain

2008

Purchase of a new production hall dedicated to metal production

2012

Establishing cooperation with Best Poland (currently Electrolux)

2014

Acquiring a new client – IFM

2016

Expansion of cooperation with MAN – metal components

2020

Further expansion of the metal plant

2024