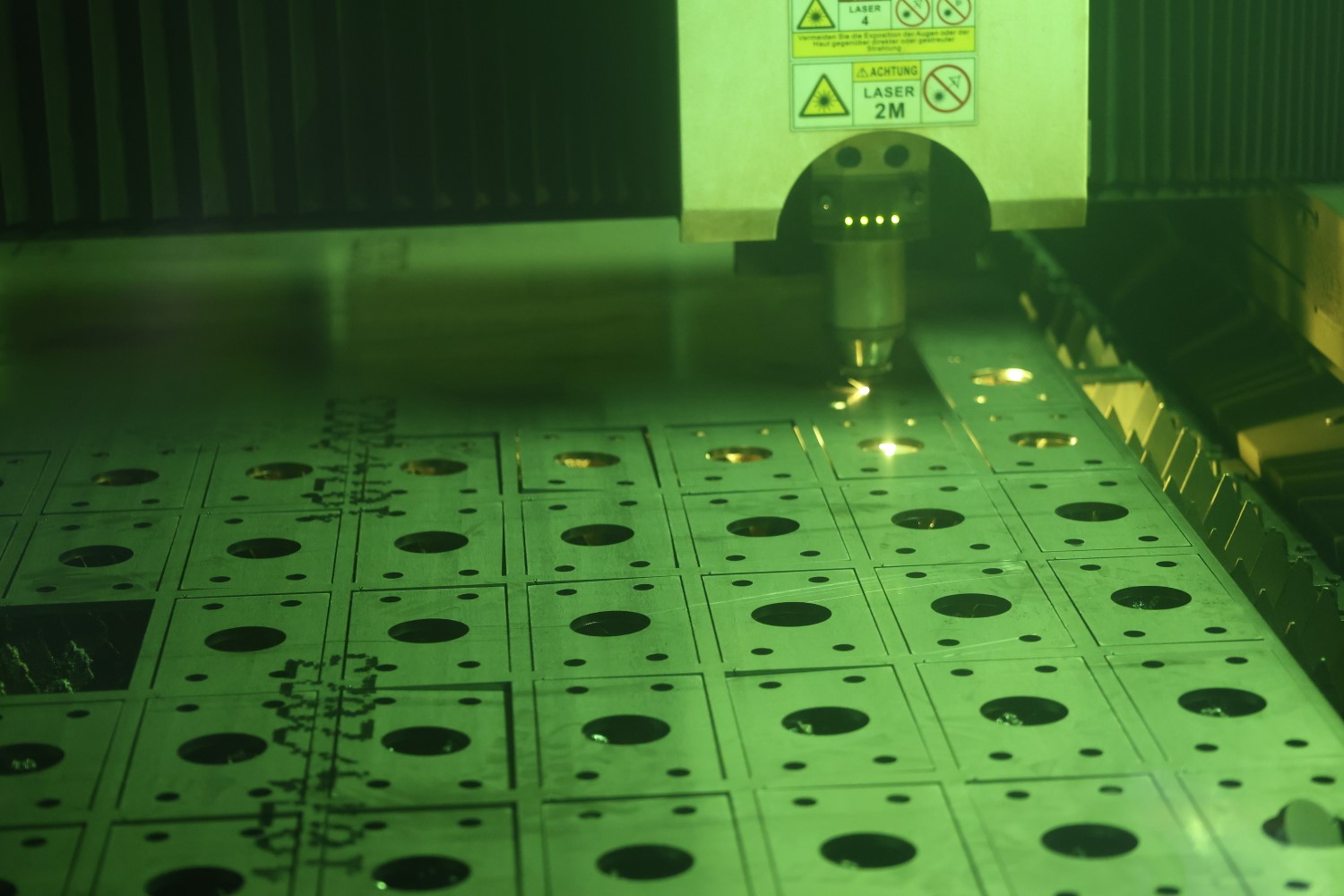

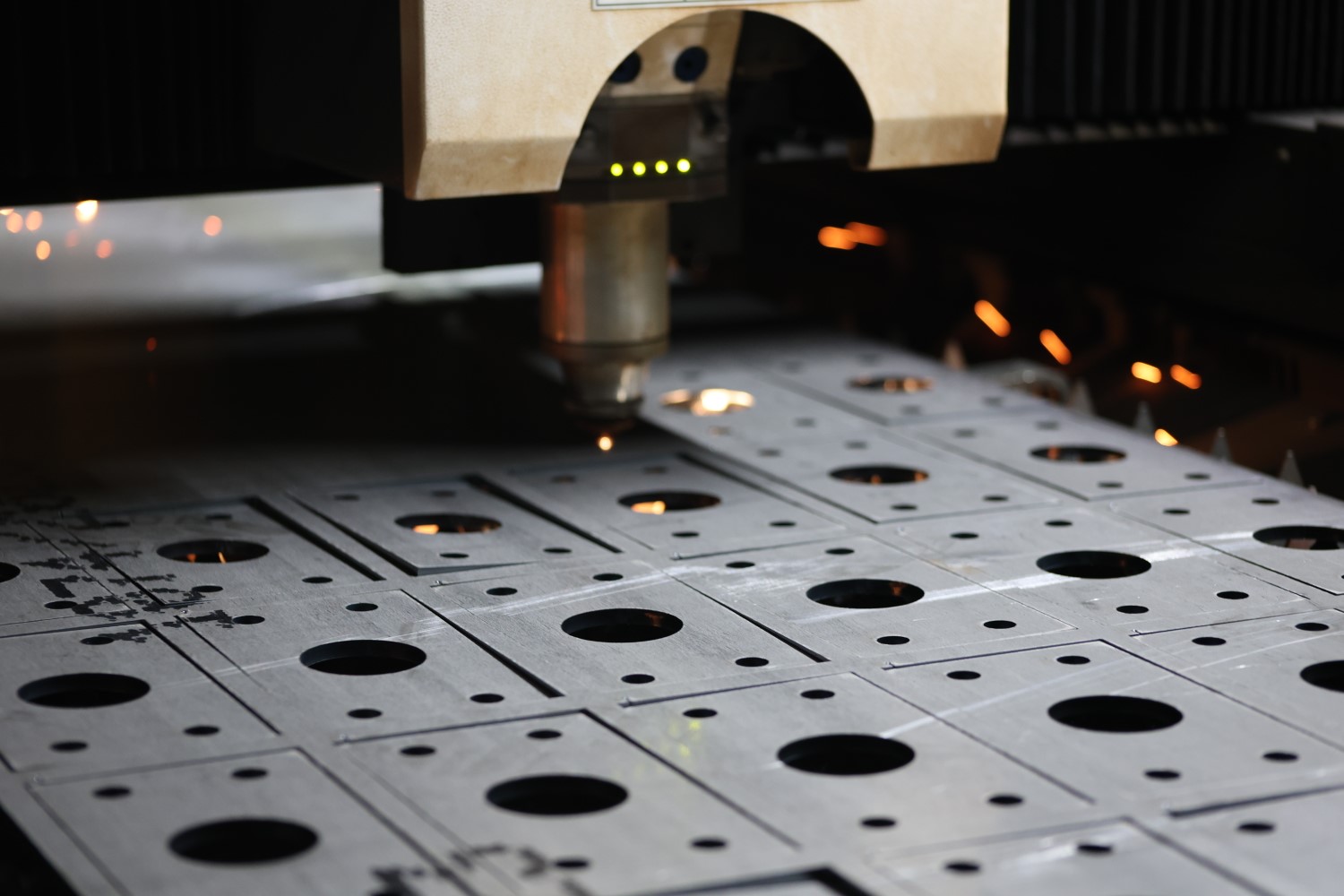

Laser cutting of sheet metal

Laser cutting is a modern, fast and most accurate method of cutting steel. It guarantees 100% dimensional repeatability of details regardless of the size of production series. We perform cutting on modern Fiber machines :

- YAWEI HLF 1530 with 4kW power output

- BYSTRONIC BYSPRINT 3015 with a power of 2kW

We process carbon steel, stainless steel, aluminum, copper and brass in thicknesses from 0.5 mm

Maximum thickness of cut materials:

- Black steel 20mm

- Stainless steel 12mm

Table dimensions 1500x3000mm

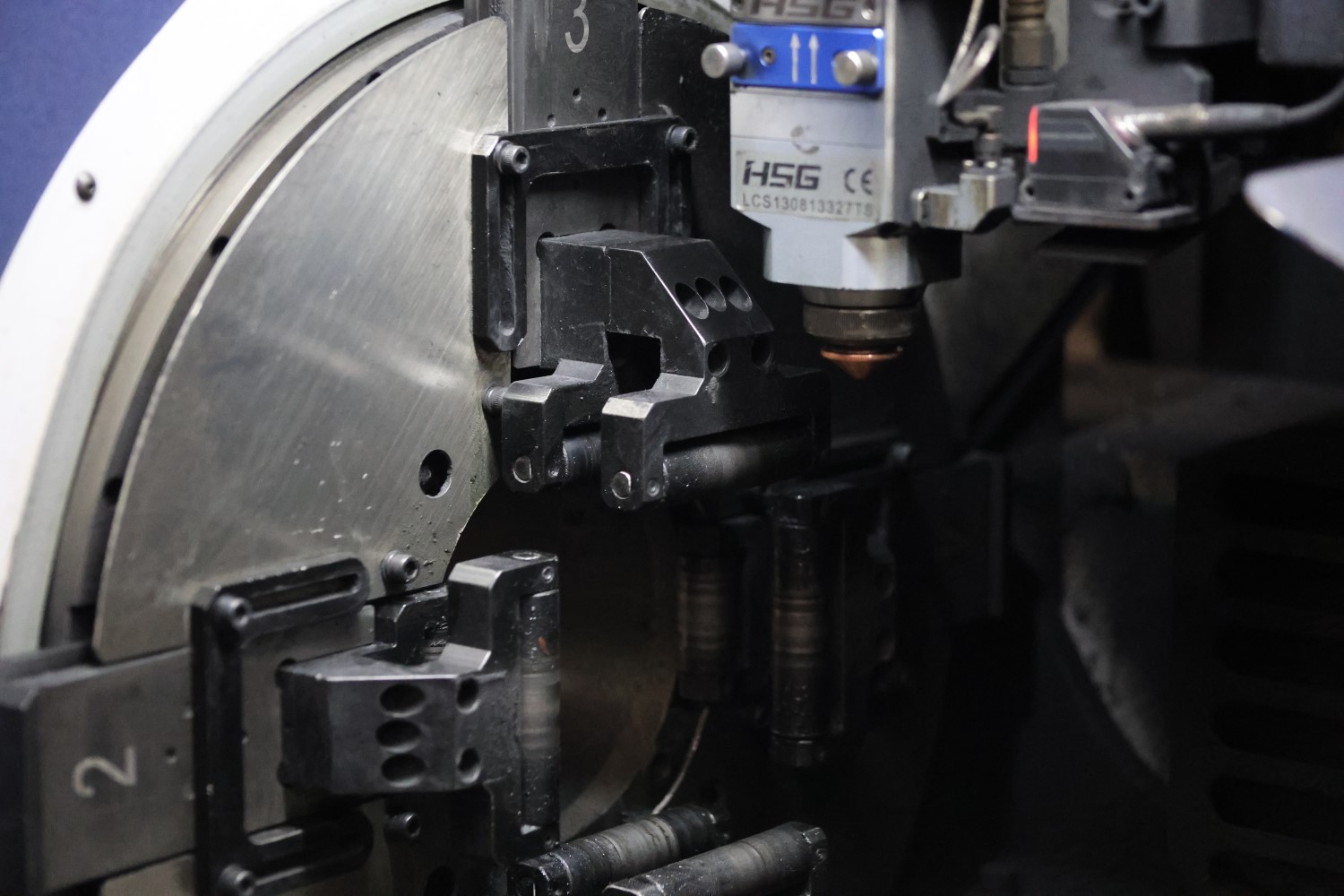

Laser cutting of pipes and profiles

Laser cutting of tubes and profiles allows us to make individual parts to make their subsequent assembly easier and faster. Laser cutting of various shapes and locks in pipes and profiles makes it possible to obtain a better connection of details, so we can reduce welding. Laser cutting of locks in profiles helps in precise positioning of individual workpieces between each other, and thus precise joining.

We do the cutting on a 1.5kW HSG TM-65 laser with a 6500mm stock

The cross sections we can cut on it:

- Profiles from 10x10mm to 80x80mm

- Pipes from fi 10mm to fi 100mm

Maximum thickness of cut materials:

- Black steel 8mm

- 5mm stainless steel.

Maximum length of the finished part 3000mm.

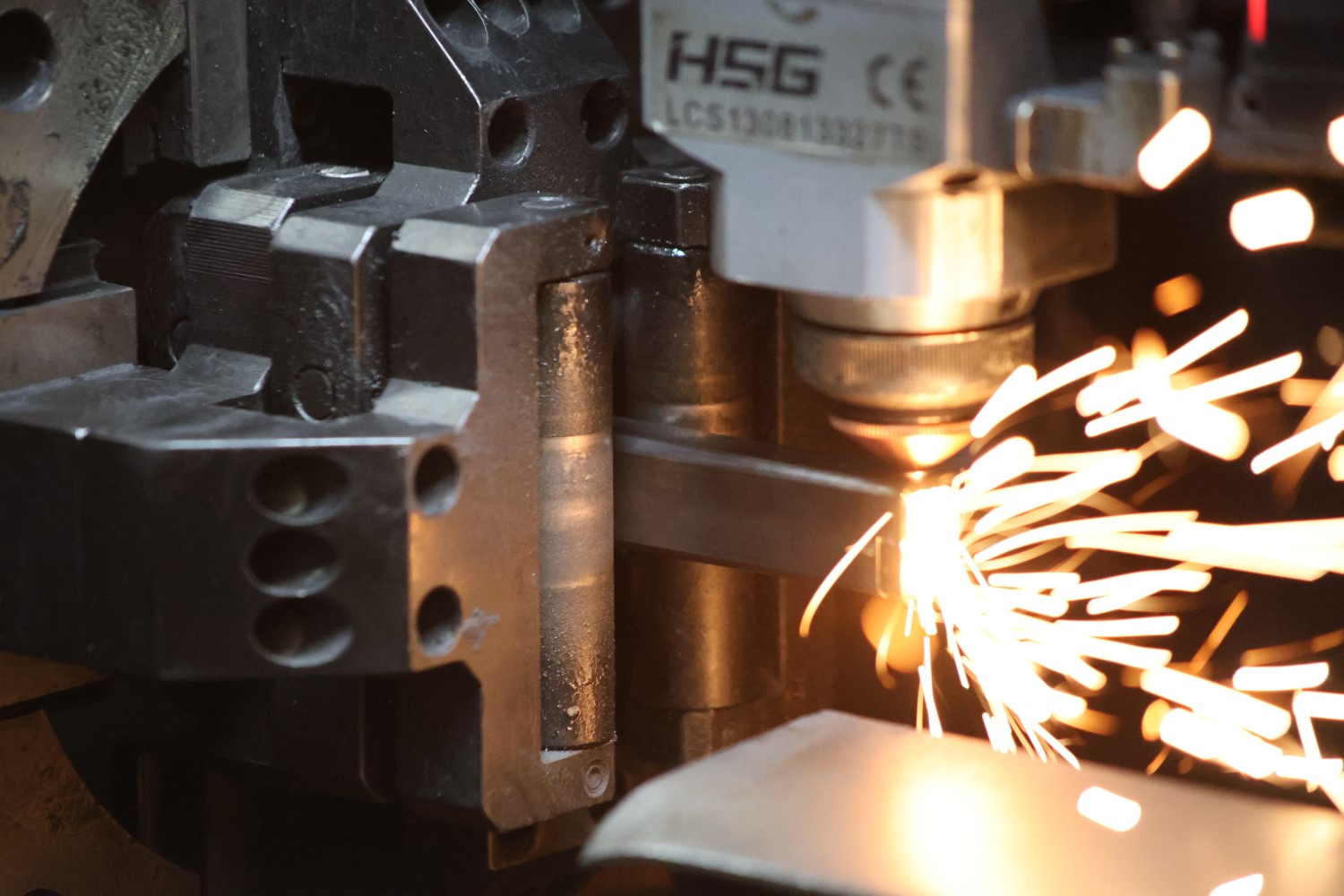

Laser cutting of pipes and profiles

Laser cutting of tubes and profiles allows us to make individual parts to make their subsequent assembly easier and faster. Laser cutting of various shapes and locks in pipes and profiles makes it possible to obtain a better connection of details, so we can reduce welding. Laser cutting of locks in profiles helps in precise positioning of individual workpieces between each other, and thus precise joining.

We do the cutting on a 1.5kW HSG TM-65 laser with a 6500mm stock

The cross sections we can cut on it:

- Profiles from 10x10mm to 80x80mm

- Pipes from fi 10mm to fi 100mm

Maximum thickness of cut materials:

- Black steel 8mm

- 5mm stainless steel.

Maximum length of the finished part 3000mm.

Surface treatment

Surface finish after laser cutting on the Costa MD4 machine:

- surface grinding and burr removal

- dulling and rounding the edges to avoid sharp edges and improve the adhesion of anti-corrosion coatings

Maximum width of the grinded detail 1150mm

Thickness range of grinded details: 0.5-150mm

Press brake bending, rolling and sheet metal stamping

- Sheet metal bending using Safan Darley press brakes with a pressure of 110 tons, Cone 900 with a pressure of 40 tons and Trumpf TruBend with a pressure of 120 tons. The maximum length of the bent element is 3 meters

- We perform sheet metal stamping on an Amada machine with a pressure of 200 tons.

- Rolling and coiling of sheets on a Haco machine with a maximum detail length of 1500 mm and a diameter of over 160 mm

Press brake bending, rolling and sheet metal stamping

- Sheet metal bending using Safan Darley press brakes with a pressure of 110 tons, Cone 900 with a pressure of 40 tons and Trumpf TruBend with a pressure of 120 tons. The maximum length of the bent element is 3 meters

- We perform sheet metal stamping on an Amada machine with a pressure of 200 tons.

- Rolling and coiling of sheets on a Haco machine with a maximum detail length of 1500 mm and a diameter of over 160 mm

CNC processing

Machining, turning and milling

- Our vertical CNC machining center Mikron VCE 1200 Pro and Mikron VCE 800 Pro

- CNC lathes with live tooling- Haas ST-30Y and Avia Turn 50

Electrical Discharge Machining

Geo Fisher Agiecharmilles CUT-20P

Kimla BFN-2030 five-axis CNC milling machine

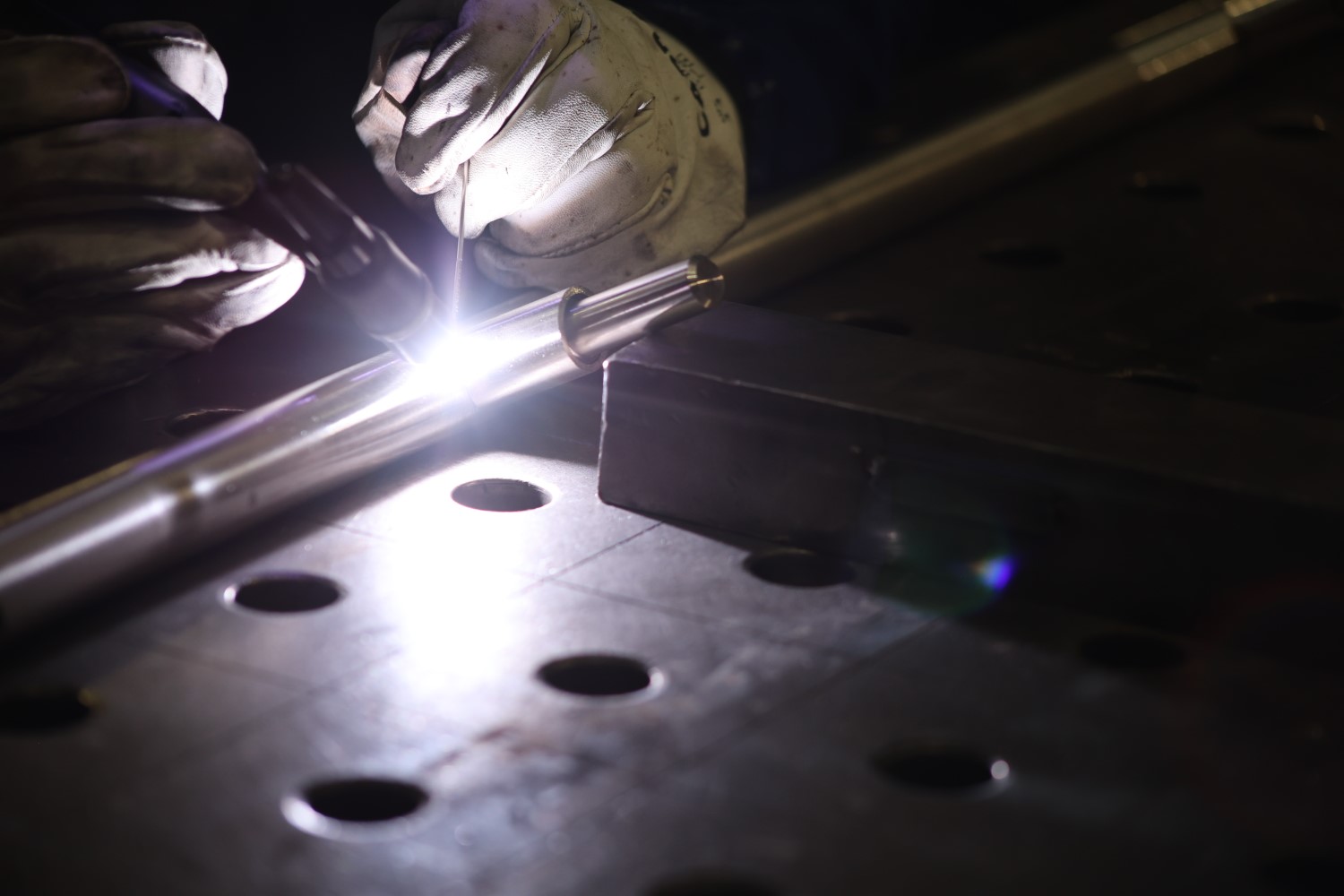

Welding

Our company also specializes in manual welding using MIG MAG and TIG methods, as well as robotic welding using the MAG method. We perform spot welding and stud welding using resistance and resistance welders. Thanks to this, we can connect different types of steel with high strength.

We have the welding standard PN-EN ISO 3834-2 and qualified personnel for testing VT1 and VT2 welds

Welding

Our company also specializes in manual welding using MIG MAG and TIG methods, as well as robotic welding using the MAG method. We perform spot welding and stud welding using resistance and resistance welders. Thanks to this, we can connect different types of steel with high strength.

We have the welding standard PN-EN ISO 3834-2 and qualified personnel for testing VT1 and VT2 welds

Manufacturing assembly

We have the ability to assemble fasteners, such as pins and pressed nuts, as well as assemble rivet nuts.

Thanks to our qualified staff, we carry out large projects with comprehensive assembly of all components, thanks to which our customers receive ready-made devices from us.

Annealing and heat treatment

Annealing of steel – a heat treatment operation for metals consisting in heating the steel to a specific temperature, keeping it there for a specific time, and then slowly cooling.

We have two chambers for annealing large elements after welding. The first has dimensions of 1700x2000x1250, the second has dimensions of 3500x2400x2000mm. We carry out these processes at temperatures up to 950ºC, ensuring optimal mechanical properties of the elements.

Annealing and heat treatment

Annealing of steel – a heat treatment operation for metals consisting in heating the steel to a specific temperature, keeping it there for a specific time, and then slowly cooling.

We have two chambers for annealing large elements after welding. The first has dimensions of 1700x2000x1250, the second has dimensions of 3500x2400x2000mm. We carry out these processes at temperatures up to 950ºC, ensuring optimal mechanical properties of the elements.

Anti-corrosion coatings

Coatings made in cooperation with certified suppliers, i.e.:

– cataphoretic painting – KTL,

– powder coating,

– wet painting,

– zinc coatings,

– zinc-nickel coatings

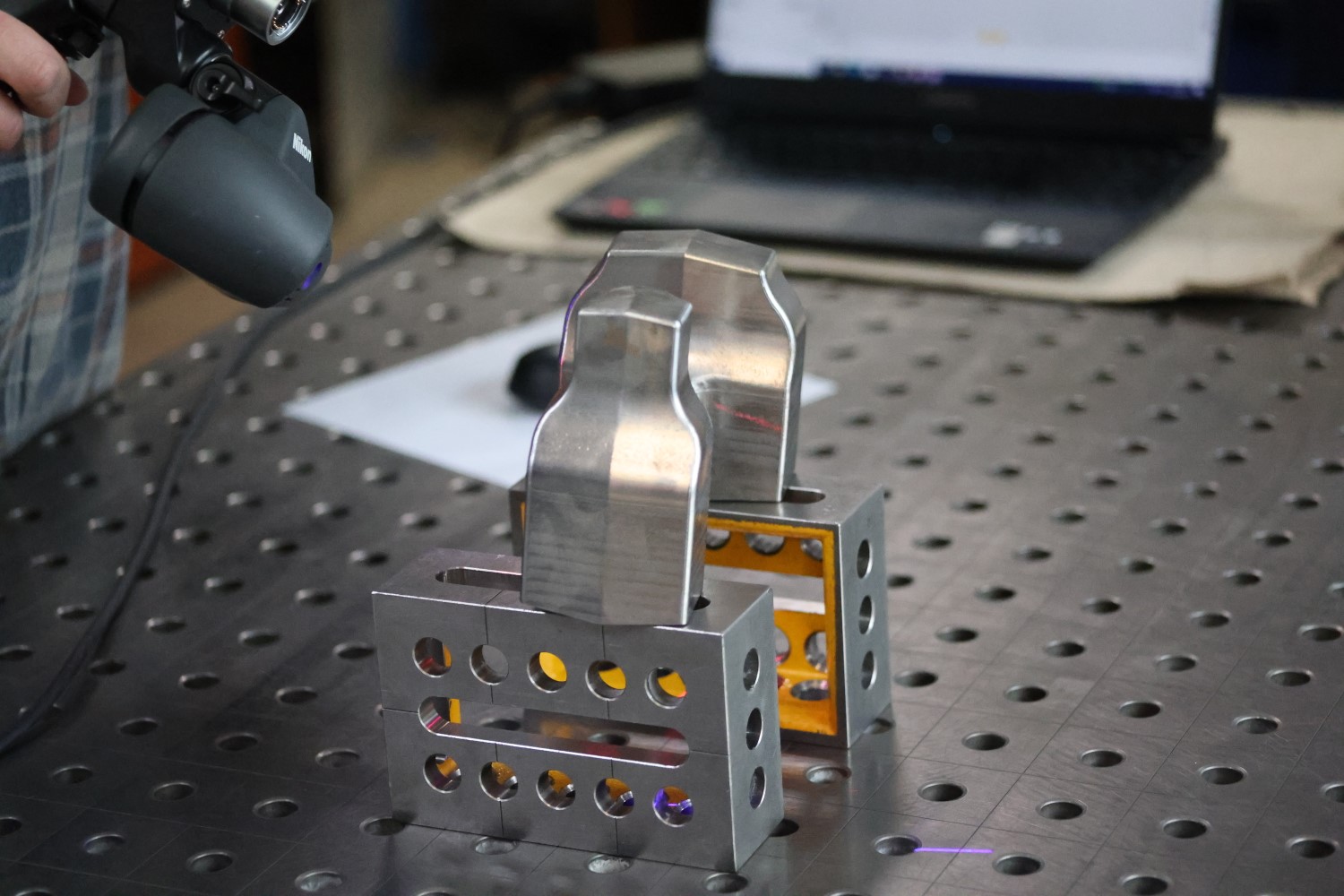

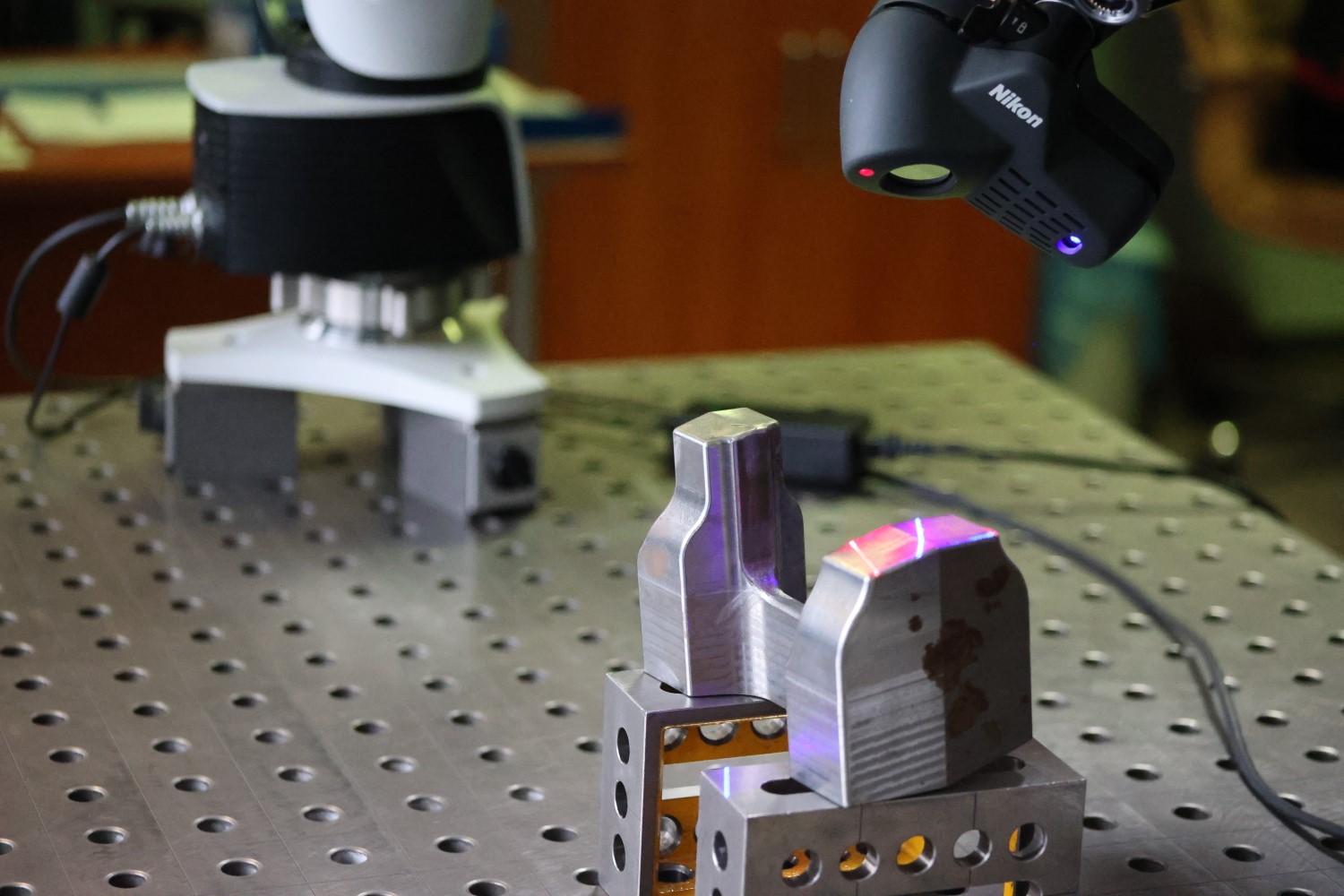

Prototypes and reverse engineering

In our prototyping department, engineers develop designs using reverse engineering technology. Thanks to 3D scanning, we can create a digital model of each detail, which we then use to develop full technical documentation.

Prototypes and reverse engineering

In our prototyping department, engineers develop designs using reverse engineering technology. Thanks to 3D scanning, we can create a digital model of each detail, which we then use to develop full technical documentation.

Contact our metal department

+48 41 2759 131

metal@starpol.pl