Starpol's offer

electrical harnesses and metal components

We have been manufacturing for the automotive, industrial and household appliance industries for over 35 years. Our offer covers two main areas: electrical harnesses and metal components. Each product is manufactured in accordance with the customer’s documentation, and where necessary, we use reverse engineering. Thanks to ISO quality certificates and an extensive machine park, we guarantee precision, repeatability and timely deliveries.

Two pillars of the offer

Electrical harnesses

connection reliability

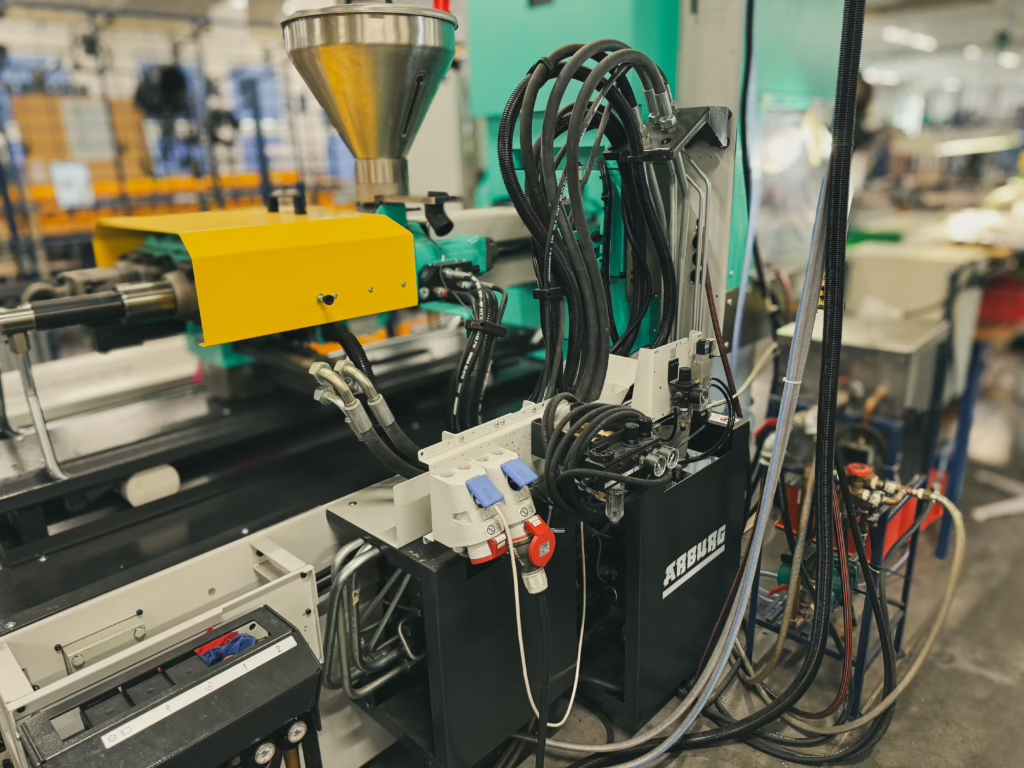

We specialise in the production of electrical harnesses for vehicles, machines and industrial equipment. The process includes wire preparation, tinning, soldering, ultrasonic welding, braiding, plastic injection moulding, assembly and full quality control.

Metal components

precision and durability

We manufacture metal components in accordance with customer documentation, and where necessary, we recreate them using reverse engineering. We use laser cutting, TIG/MAG welding, CNC machining, assembly and quality control technologies.

The technologies we use

At Starpol, we manufacture exclusively in accordance with our customers' technical documentation, using modern technologies that guarantee repeatability and the highest precision of workmanship. Each stage – from cable preparation, through soldering, welding and braiding, to the assembly of complete harnesses – is carried out using advanced CNC machines, electrical testers and inspection stations. At the same time, we offer the production of metal components, using laser cutting, TIG and MAG welding, and CNC machining. Thanks to the combination of our employees' experience and process automation, we are able to fulfil both short series and large orders for the automotive, household appliances and industrial sectors. Reverse engineering is also one of our strengths – where documentation is lacking, we are able to recreate the necessary details and prepare them for production. All products undergo certified quality control in accordance with ISO 9001 before they reach the customer. This gives customers the assurance that Starpol products meet the highest technological requirements and are fully compliant with the design specifications.

Preparing the cables

Precise CNC cutting, stripping and crimping of wires – a solid foundation for further stages of production.

Tinning wires

The tinning process protects wires from corrosion and increases the durability of soldered joints.

Soldering wires

The tinning process protects wires from corrosion and increases the durability of soldered joints.

Ultrasonic welding

Nowoczesna technologia bezlutowa – szybkie i mocne łączenie przewodów bez użycia dodatkowych materiałów. The tinning process protects wires from corrosion and increases the durability of soldered joints.

Wire braiding

Durable and aesthetic protection for bundles, protecting them from mechanical damage and wear.

Plastic injection moulding

The tinning process protects wires from corrosion and increases the durability of soldered joints.

Assembly of bundles

Comprehensive assembly of electrical harnesses, ready for installation at the customer's premises.

Quality control

The tinning process protects wires from corrosion and increases the durability of soldered joints.

Laser cutting

The tinning process protects wires from corrosion and increases the durability of soldered joints.

TIG/MAG welding

Precise welds made using the TIG/MAG method – both manual and robotic.

CNC machining

Machining in modern CNC centres, ensuring the highest repeatability and accuracy.

Assembly and quality control

The finished components undergo assembly and quality testing before delivery to the customer.

We work in accordance with the highest standards of quality and safety.

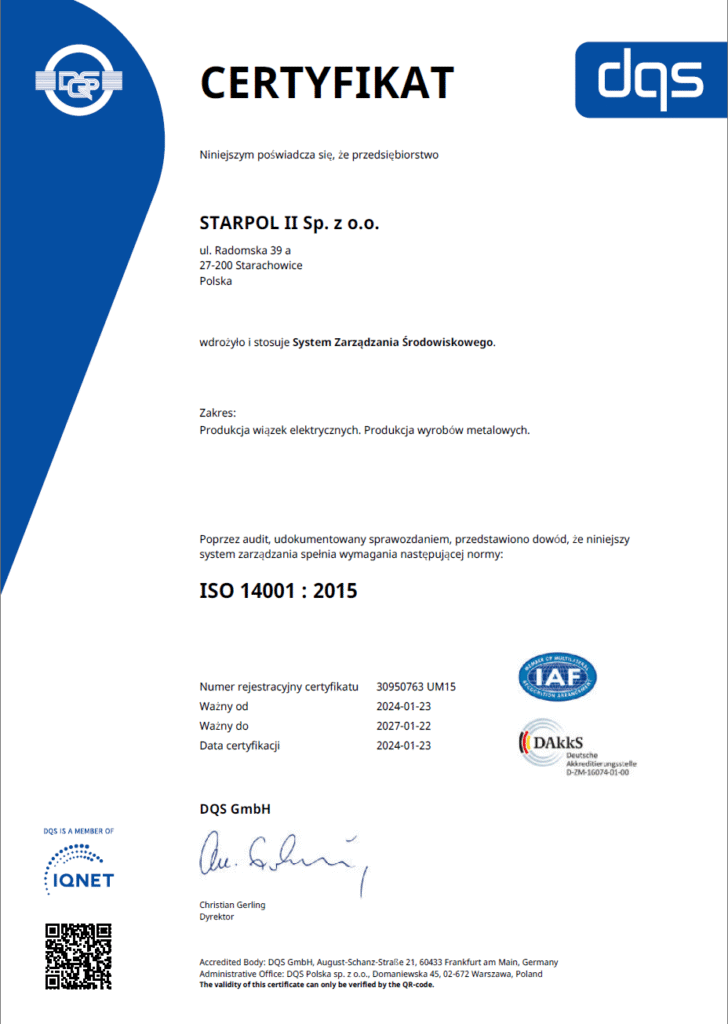

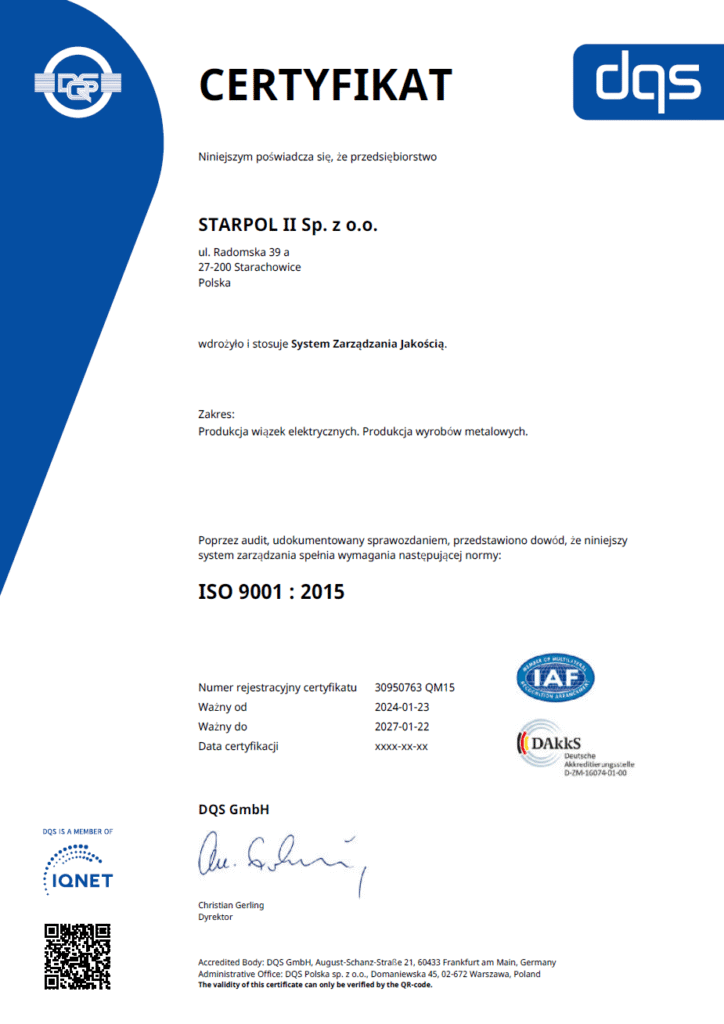

Starpol II Sp. z o.o. has for years focused on quality, safety, and production reliability. This is confirmed by the ISO certificates obtained as a result of independent audits conducted by reputable certification bodies. Thanks to them, our clients can be sure that all processes – from material purchasing, through the production of wiring harnesses and metal components, to the final inspection of finished products – are carried out in accordance with international standards.

quality management system

ISO 9001 is the most recognised quality management standard in the world. Its implementation at STARPOL enables continuous control of production processes, increased efficiency and product consistency, as well as improved customer satisfaction. This certificate confirms that every stage of our operations meets high quality requirements.

environmental management

Environmental awareness and responsibility for the natural environment are an important part of our strategy. Holding the ISO 14001:2015 certificate means that we conduct our business with respect for the environment – we minimise waste, manage energy rationally and implement solutions that limit the negative impact of production on the environment.

quality of welding processes

The welding processes carried out at STARPOL comply with the requirements of ISO 3834-2 and EN 15085-2 standards. These certificates confirm the highest quality, safety, and technical compliance of welded joints. As a result, our metal structures meet the requirements of domestic and international clients, including those in the industrial and transport sectors.

Quality certificates confirming our standards

Do you have the documentation?

We will take care of production.

Contact us and learn about the possibilities of cooperation. The Starpol team will ensure precise and certified implementation of your project – from individual orders to serial production.