Quality confirmed by certificates

We work in accordance with the highest standards of quality and safety.

Every product leaving the Starpol factory undergoes multi-stage quality control. Thanks to ISO and IATF certificates, we guarantee that our production complies with international standards.

We work in accordance with the highest standards of quality and safety.

Starpol II Sp. z o.o. has for years focused on quality, safety, and production reliability. This is confirmed by the ISO certificates obtained as a result of independent audits conducted by reputable certification bodies. Thanks to them, our clients can be sure that all processes – from material purchasing, through the production of wiring harnesses and metal components, to the final inspection of finished products – are carried out in accordance with international standards.

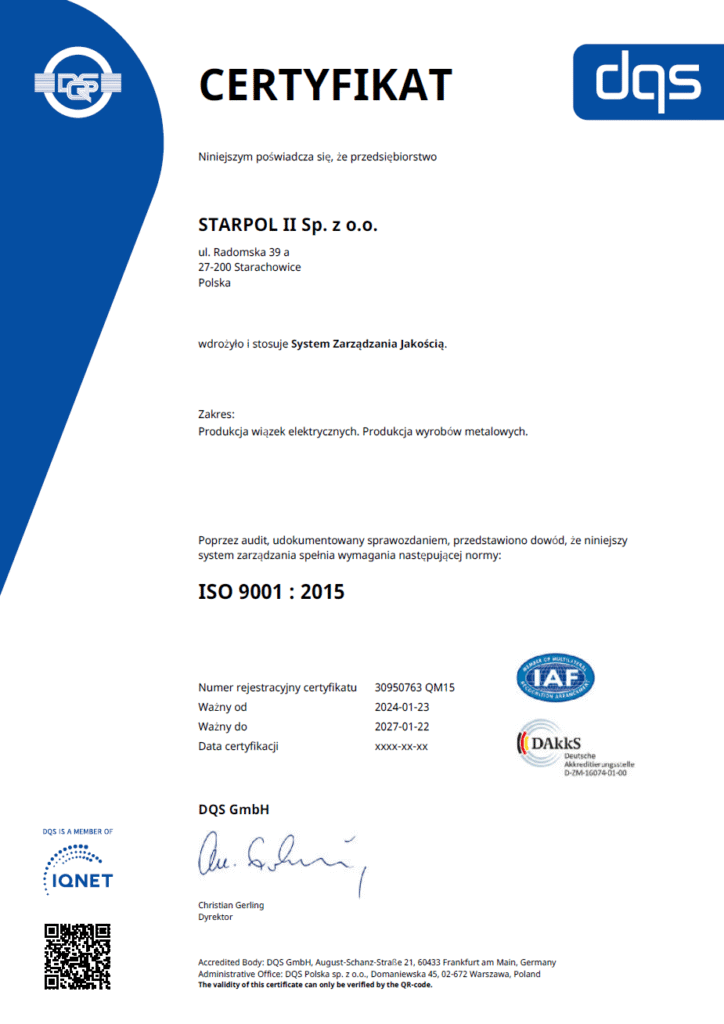

quality management system

ISO 9001 is the most recognised quality management standard in the world. Its implementation at STARPOL enables continuous control of production processes, increased efficiency and product consistency, as well as improved customer satisfaction. This certificate confirms that every stage of our operations meets high quality requirements.

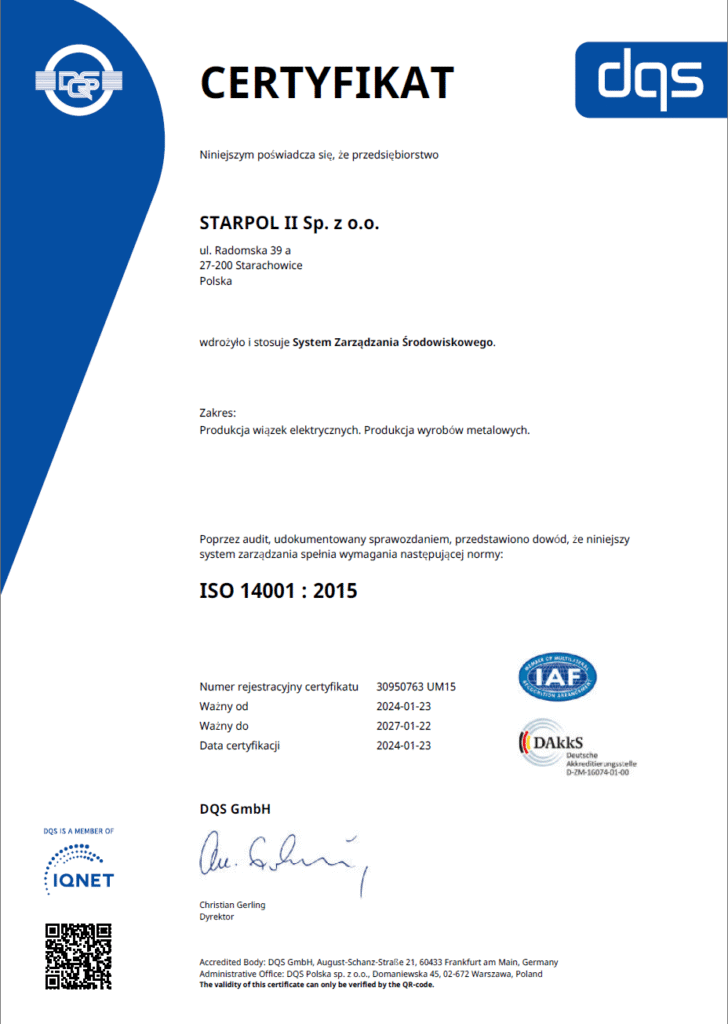

environmental management

Environmental awareness and responsibility for the natural environment are an important part of our strategy. Holding the ISO 14001:2015 certificate means that we conduct our business with respect for the environment – we minimise waste, manage energy rationally and implement solutions that limit the negative impact of production on the environment.

quality of welding processes

The welding processes carried out at STARPOL comply with the requirements of ISO 3834-2 and EN 15085-2 standards. These certificates confirm the highest quality, safety, and technical compliance of welded joints. As a result, our metal structures meet the requirements of domestic and international clients, including those in the industrial and transport sectors.

Quality certificates confirming our standards

Multi-stage production control

The quality process at STARPOL begins at the documentation analysis stage and covers every phase of production – from incoming material inspection, through technological processes, to the testing of finished products. We use modern laboratories and measuring equipment to ensure repeatability and reliability.

How do we ensure quality?

The quality process at STARPOL II Sp. z o.o. is a coherent system covering all stages – from design and material selection to final testing. As a result, every product meets ISO certification requirements and customer expectations.

Analysis of customer documentation

The quality process begins with a detailed review of the design and the customer's technical requirements. This allows us to properly prepare production and define control standards.

Inspection of incoming materials

Every component and raw material is subject to verification – from compliance with documentation to laboratory testing. In this way, we eliminate the risk of using materials that do not meet the requirements.

Production processes

Production is carried out in accordance with procedures compliant with ISO 9001, ISO 14001 and ISO 3834-2 certificates. Constant quality control ensures repeatability and full compliance with requirements.

Final tests and acceptance

Finished products undergo detailed electrical, mechanical and visual testing. Only after positive verification do they reach customers as products that fully comply with their design.

What do our customers gain?

Cooperation with Starpol II Sp. z o.o. is a guarantee of quality and safety. Thanks to ISO certificates and strict production control, we deliver products that meet industry requirements and the expectations of the most demanding partners.

Reliability

Consistent quality at every stage of production – from materials to finished product. Our processes comply with ISO 9001 .

Safety

Production in line with international industry and environmental standards ISO 14001, guaranteeing safety of use.

Trust

Many years of experience, external audits and quality certificates build lasting relationships with our partners. Contact us to join the group of satisfied customers.

The figures speak for themselves.

With over 35 years of experience in the market, Starpol II Sp. z o.o. is a trusted partner for contractors in Poland and abroad. Our achievements are best demonstrated by the hard figures that stand behind our quality and reliability.

35+ lat doświadczenia

Over three decades of presence on the market of electrical harnesses and metal components.

100+ clients

The trust of hundreds of domestic and international customers.

3000+ projects

Thousands of projects completed in accordance with contractors' requirements.

2M+ products sold

Over two million products delivered that meet ISO standards.

Jakość w liczbach

F.A.Q.

Frequently asked questions

ISO 9001 certified and continuously improved. This ensures repeatable quality, full traceability and compliance with customer requirements. See also our technologies.

ISO 14001 oznacza, że minimalizujemy wpływ na środowisko: racjonalizujemy zużycie energii, prowadzimy selektywną gospodarkę odpadami i zapobiegamy incydentom środowiskowym. To standard potwierdzony audytami.

Te normy potwierdzają jakość i bezpieczeństwo procesów spawalniczych: kwalifikacje personelu, procedury WPS oraz kontrolę NDT/VT. Stosujemy je w produkcji elementów metalowych i konstrukcji.

Pracujemy na dokumentacji klienta. Kontrolujemy materiały wejściowe, monitorujemy procesy, a gotowe wyroby przechodzą testy elektryczne, mechaniczne i wizualne. Szczegóły w sekcji Jakość.

Tak — udostępniamy aktualne certyfikaty ISO 9001, ISO 14001 oraz ISO 3834-2 / EN 15085-2. Skontaktuj się z nami: formularz kontaktowy.

Check out our technologies in practice

Certified quality is just the beginning. See how Starpol II Sp. z o.o.’s modern machine park supports precision and reliability in production.