Injection moulding of plastic components

In the injection moulding process, we manufacture plastic components that serve as

insulation, fasteners and cable glands. This stage combines functionality with aesthetics and precision.

Precision components for electrical harnesses

We use the injection moulding process to form protective and mounting elements for cable harnesses: cable glands, connector insulation, sockets and fasteners. Thanks to automation and parameter control, we achieve high repeatability and surface quality.

Together with our partners, we design and manufacture injection moulds dedicated to specific projects. This allows us to ensure that the component is optimally suited to the requirements of the application and the working environment.

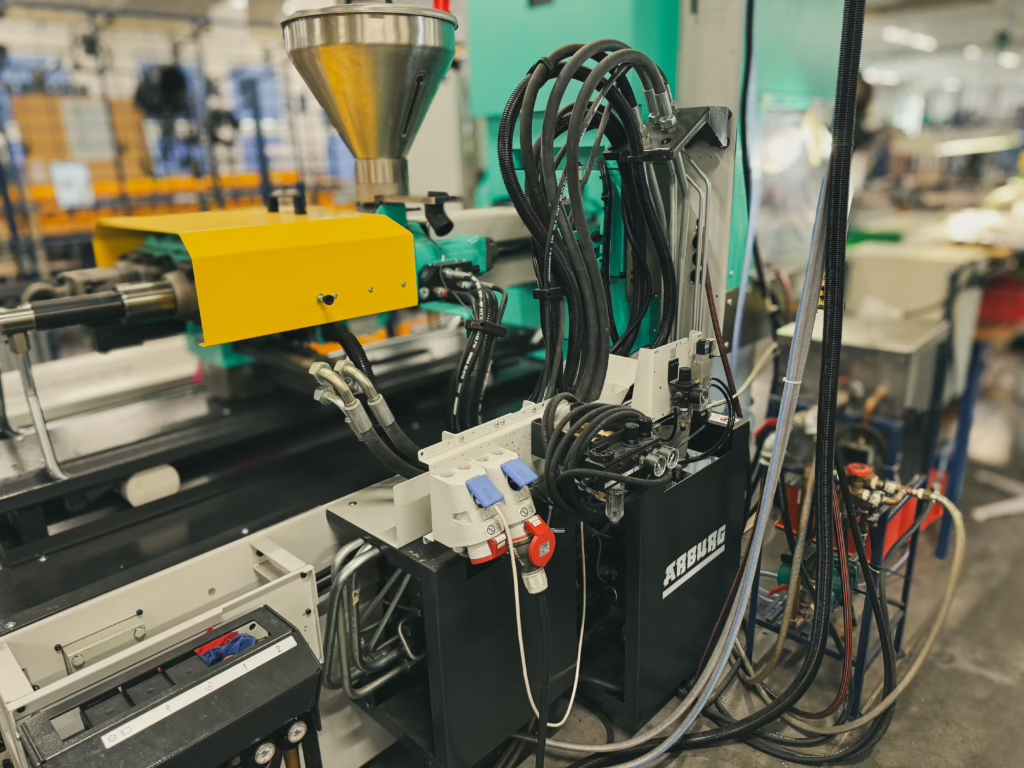

Injection moulding machines and workstations

Nasz park maszynowy obejmuje nowoczesne wtryskarki Arburg i Battenfeld, które umożliwiają formowanie komponentów o różnych rozmiarach i geometrii. Sterowanie numeryczne pozwala na precyzyjne ustawianie parametrów czasu wtrysku, ciśnienia i chłodzenia.

Injection

The process can be combined with insert moulding (with metal elements) and two-stage injection moulding for greater component functionality.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Advantages of injection moulding

Protection and durability

Plastic components protect sensitive connectors and bushings from moisture, dust and vibrations.

Chemical resistance

Materials are selected for contact with oils, fuels and other aggressive agents.

Electrical insulation

The injection material provides additional insulation for the connectors and ensures the safety of use of the finished harnesses.

Quality control of moulding

Each plastic component undergoes dimensional inspection and visual inspection. We verify mould filling, surface smoothness and material integrity. If necessary, we perform thermal and mechanical resistance tests.

Visual inspection

Strength tests

Measurement of dimensions

RELATED PROCESSES

Welding of joints

Provides durable, low-resistance wire connections prior to injection moulding of the sheath.

Braiding

Reinforcing the bundle and preparing for injection of insulation or mounting covers.

Final assembly

Final assembly of components with moulded parts and electrical testing.

Let us handle this process for you.

Take advantage of our offer covering this stage of production and receive full technological support.

Injection moulding

Injection moulding of protective and mounting elements – precision and repeatability in every series.

Do you have the wiring documentation?

Do you require moulded components for your harnesses?

We will develop a mould design, select the material and manufacture components with the highest precision.