Process Precision and Repeatability

At STARPOL, the crimping process is carried out using proven technologies and a modern machine park. This ensures full quality control and high production repeatability – from prototype development to high-volume serial production.

Technology Selection for Specific Applications

Crimping technology is always selected individually, taking into account:

- connector type,

- wire cross-section,

- technical documentation requirements,

- production volume.

Depending on the project, mechanical, pneumatic, and hydraulic presses are used to provide stable and precise connections between wires and terminals. Wire cross-sections up to 300 mm² are supported, enabling the implementation of applications requiring high crimping forces.

Manual and semi-automatic stations are used for short series and prototypes, while automated stations and high-efficiency production lines are applied for serial and high-volume manufacturing.

Crimping Process and Quality Control

Every crimp performed at STARPOL is subject to process control. Production stations are equipped with crimp force monitoring systems that allow for:

- real-time parameter monitoring,

- detection of deviations during production,

- maintaining consistent quality throughout the entire batch.

The process is complemented by mechanical and electrical inspections, destructive testing, and audits of tooling and crimping parameters. This ensures full compliance with quality requirements and industry standards.

Automation and Process Integration

Modern automatic machines for cutting, stripping, and end processing of wires are used in cable preparation, integrating multiple operations within a single working cycle. This approach increases production efficiency, minimizes the risk of manual errors, and ensures high parameter repeatability.

Crimping stations are part of integrated production lines cooperating with wire marking systems and internal material handling equipment. This guarantees smooth material flow and optimization of the entire production process.

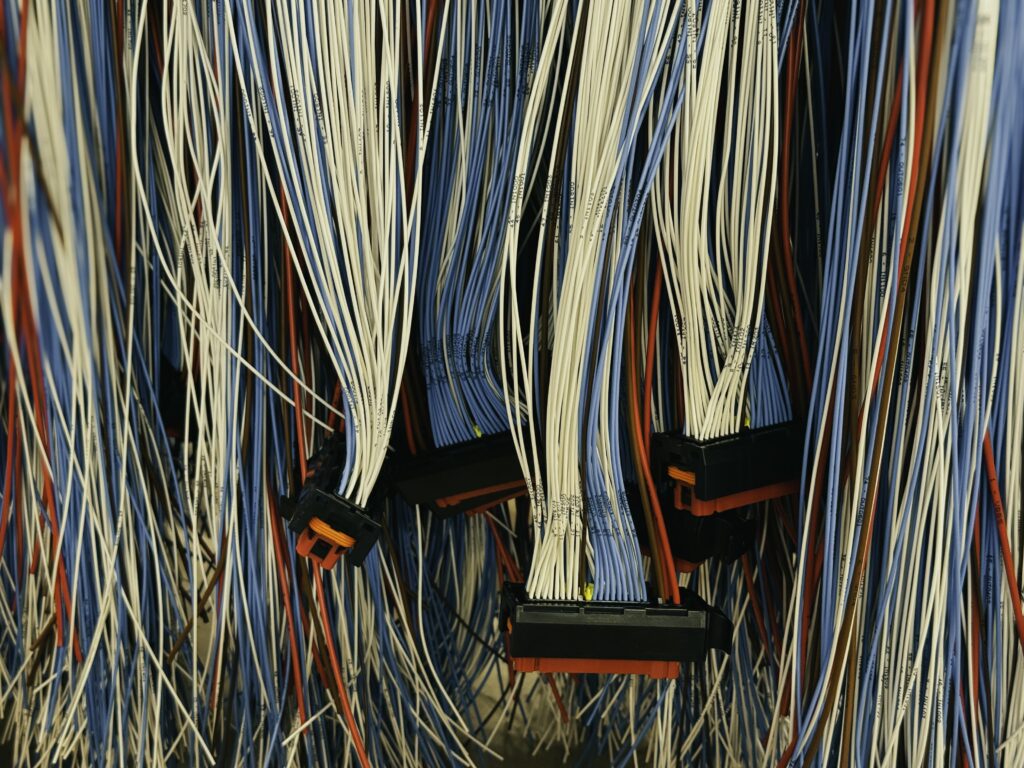

Crimping as Part of a Complete Wire Harness Manufacturing Process

At STARPOL, cable crimping is an integral part of the complete wire harness manufacturing process. After durable and controlled connections are made, the cables proceed to subsequent stages such as harness assembly, additional processing operations, and final quality inspection.

As a result, customers receive complete and reliable electrical wire harnesses prepared in accordance with technical documentation and application-specific requirements.

From Prototype to Serial Production

STARPOL delivers projects at every stage of product development – from single cables and prototypes, through short test series, to serial and high-volume production. Crimping technology is precisely matched to project requirements, ensuring process stability, repeatability, and high final quality.

Technical Support and Cooperation

Customers with wire documentation can rely on the selection of appropriate technology, equipment, and process parameters. STARPOL provides technical support at every stage – from prototype development to serial production.