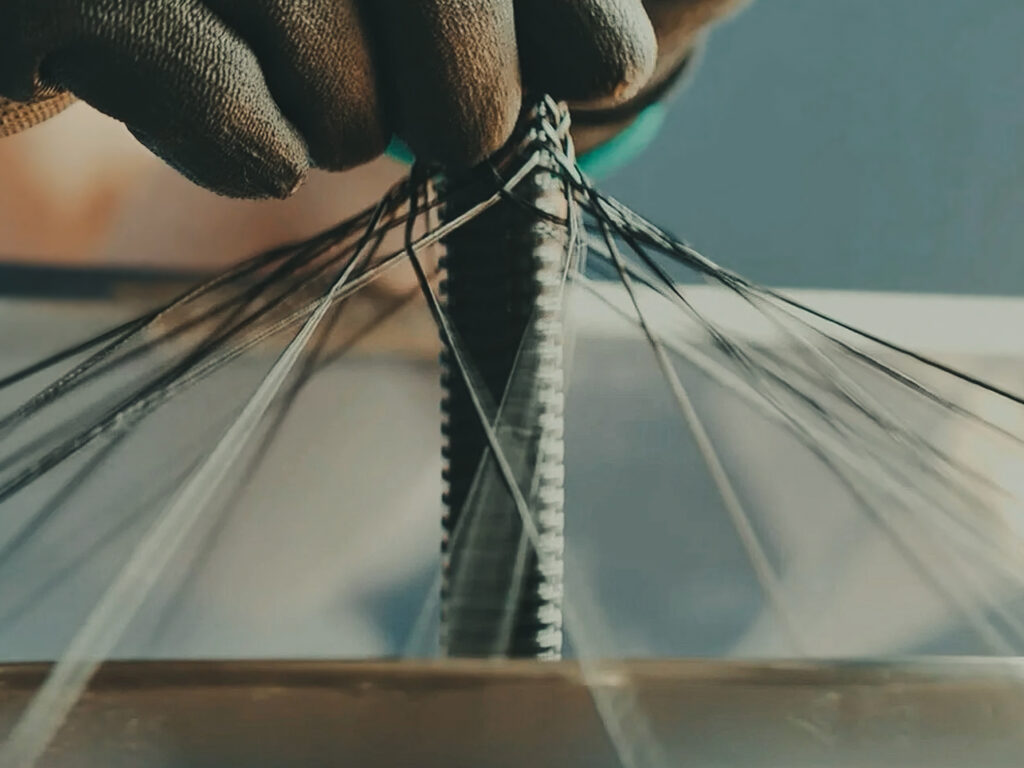

Electrical harness braiding

Braiding combines aesthetics with mechanical and thermal protection. We use it where harnesses operate

in harsh conditions and require increased resistance to abrasion, temperature and moisture.

Protection and order in demanding applications

We perform braiding using string/braid and materials selected for the working conditions of the harness. This solution ensures abrasion resistance, improves thermal and electrical insulation and can increase the fire resistance of the entire cable assembly.

The process is carried out on dedicated workstations and braiding machines, which guarantees repeatable tension and uniform braiding along the entire length of the harness.

Braiding machines

We use harness braiding machines that ensure stable tension and an even, aesthetic braid structure. For non-standard components, we use manual stations operated by experienced operators.

Materials and methods of braiding

Mechanical protection

The braided cord provides high abrasion resistance and protects the harness at critical mounting points.

Thermal resistance

We select materials with the appropriate operating temperature and flammability class for the application environment.

Aesthetics and order

The braid binds the bundle branches together and improves the aesthetics of cable routing within the device.

When should braiding be used?

Industrial conditions

Vibrations, sharp edges, frequent servicing.

External environments

Increased moisture, dust and pollution.

Automotive / mobile

Bundles operating in motion and at variable temperatures.

Service installation

When the harness is frequently reconnected and requires reinforcement.

Quality control of the braid

We check the tension and adhesion of the braid, the stability of the ends and the abrasion resistance in areas exposed to contact with structural elements. If necessary, we perform mechanical tests and visual inspection of 100% of the products.

Visual inspection

Abrasion resistance test

Checking length and ends

RELATED PROCESSES

Bundle strapping

The process of creating a braid from fishing line or fibre, providing additional protection and aesthetics.

Marking

Permanent identifiers for cables and connectors in accordance with documentation.

Final assembly

Final assembly with electrical and mechanical inspection.

Let us handle this process for you.

Take advantage of our offer covering this stage of production and receive full technological support.

Bundle wrapping

Aesthetic and durable braids – protection of cables against abrasion and temperature.

Do you have the wiring documentation?

Do you require a braid that is suited to your working conditions?

We will select the material and braiding method for your application – from prototypes to production series.