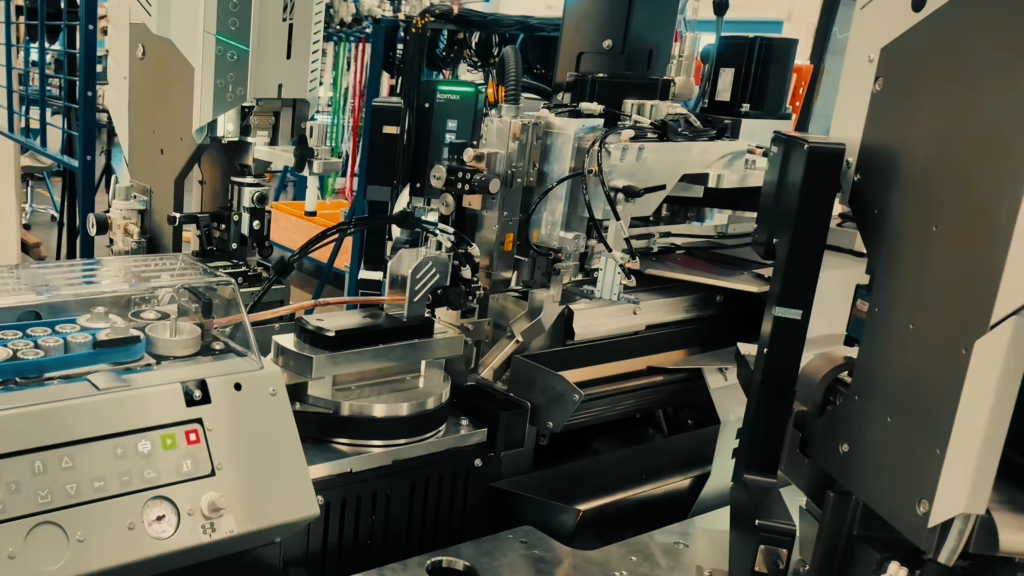

In the STARPOL machine park, there is an advanced cable processing machine — the Schleuniger PowerStrip 9550.

This system is designed for precise cutting and stripping of single- and multi-core cables (see also multi-core cable machines). It perfectly prepares cables for the next production stages: soldering, ultrasonic welding, braiding, and final assembly.

Also check our service: cutting • stripping • crimping of cables.

Thanks to this technology, it is possible to produce wiring harnesses with the highest precision and repeatability, in line with the requirements of the automotive, industrial and electronics sectors.

Why the Schleuniger PowerStrip 9550 stands out in STARPOL production:

- Precise cutting and stripping – accurate preparation of cables with various lengths, diameters and insulation types (learn more about the cutting and processing stage)

- High efficiency – short cycle time, continuous operation and minimal material waste (see the entire production process)

- Flexible configuration – quick changeover and setup tailored to customer specifications (see crimp-centre machines)

- Certified quality – compliance with ISO 9001 and ISO 3834-2 standards (see our certificates and quality control system)

The PowerStrip 9550 is a key element of automation in our facility, and the processed cables move on to:

tinning,

soldering,

ultrasonic welding,

braiding and

final harness assembly.

Watch the video of the Schleuniger PowerStrip 9550 operating in our production hall:

YouTube: Schleuniger PowerStrip 9550 at STARPOL

https://www.youtube.com/watch?v=Xc9IDNVdpJE

See also

- Machine park • Technologies • Production process

- Other cable processing machines:

Komax Alpha 520,

Wirmec AM 300 Quattro,

Schleuniger MultiStrip 9480 - Cable joining methods: overview • soldering • ultrasonic welding

- Component forming: injection moulding • plastic injection

- Quality and standards: quality control • certificates

- News • Careers • Contact