Production of electrical harnesses – Starpol

We manufacture customised electrical harnesses in accordance with technical documentation provided by the customer. Our solutions are used in the automotive, industrial, energy, telecommunications and consumer electronics industries. Thanks to our modern machine park and certified quality control, we ensure process repeatability and reliability of finished cable harnesses – both in short prototype series and in mass production.

Why choose Starpol electrical harnesses?

Electrical harnesses are a key component of power supply and control systems. Any mistake in production can result in costly downtime or the risk of failure. That is why our customers entrust us with responsible projects, knowing that they can count on:

Modern machinery park

We use Komax Alpha and Gamma machines, Schleuniger machines, and Branson and Sonobond ultrasonic welding stations. This guarantees repeatability and high efficiency.

Flexible customised production

We manufacture both individual prototypes and large series for the automotive and industrial sectors. Each order is tailored to the specific requirements of the customer.

Certified quality

We hold ISO 9001:2015, ISO 14001:2015 and ISO 3834-2 certifications. Each harness undergoes electrical, visual and functional testing.

Fast turnaround times

Thanks to process automation and well-organised production, we are able to fulfil orders on time, even for large volumes.

How we provide this service

See the technological stages involved in this offer – from cable preparation to installation and testing.

Cutting and processing of cables

Automatic cut & strip, printing on the fly, preparation for further operations.

Assembly of bundles

Taping, braiding, marking and final inspection.

Wire end processing

Crimping, soldering, ultrasonic welding and IDC connectors.

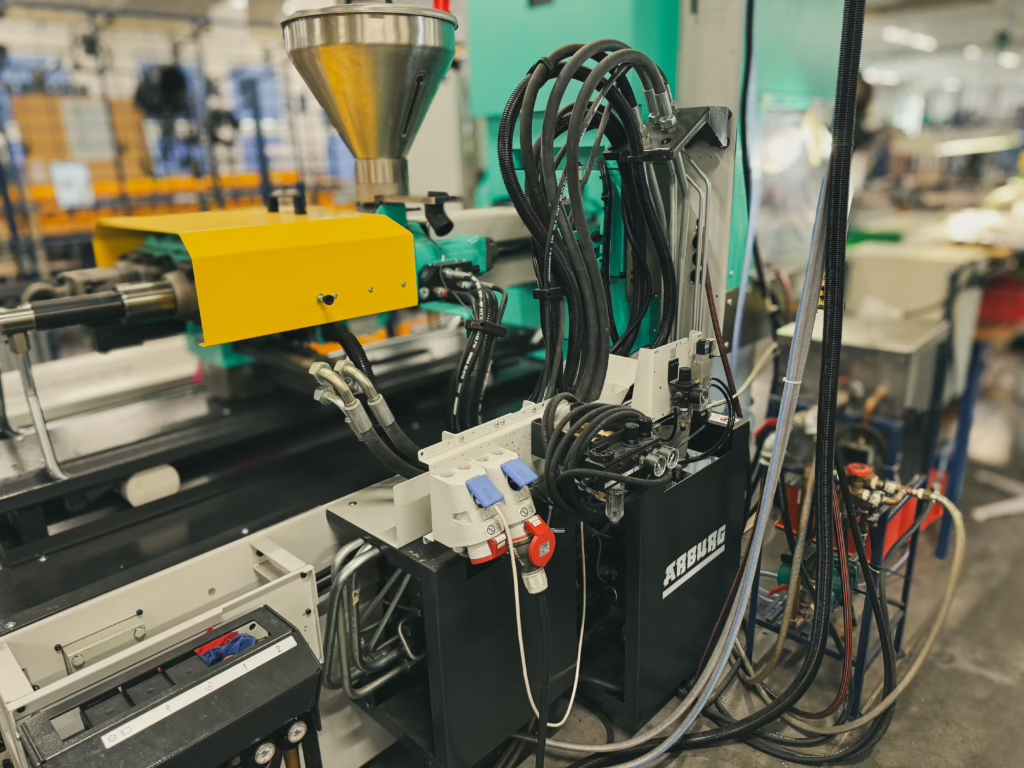

Injection moulding

Elementy ochronne i montażowe z tworzyw, dopasowane do projektu.

The technologies we use

At Starpol, we manufacture exclusively in accordance with our customers' technical documentation, using modern technologies that guarantee repeatability and the highest precision of workmanship. Each stage – from cable preparation, through soldering, welding and braiding, to the assembly of complete harnesses – is carried out using advanced CNC machines, electrical testers and inspection stations. At the same time, we offer the production of metal components, using laser cutting, TIG and MAG welding, and CNC machining. Thanks to the combination of our employees' experience and process automation, we are able to fulfil both short series and large orders for the automotive, household appliances and industrial sectors. Reverse engineering is also one of our strengths – where documentation is lacking, we are able to recreate the necessary details and prepare them for production. All products undergo certified quality control in accordance with ISO 9001 before they reach the customer. This gives customers the assurance that Starpol products meet the highest technological requirements and are fully compliant with the design specifications.

Preparing the cables

Precise CNC cutting, stripping and crimping of wires – a solid foundation for further stages of production.

Tinning wires

The tinning process protects wires from corrosion and increases the durability of soldered joints.

Soldering wires

The tinning process protects wires from corrosion and increases the durability of soldered joints.

Ultrasonic welding

Nowoczesna technologia bezlutowa – szybkie i mocne łączenie przewodów bez użycia dodatkowych materiałów. The tinning process protects wires from corrosion and increases the durability of soldered joints.

Wire braiding

Durable and aesthetic protection for bundles, protecting them from mechanical damage and wear.

Plastic injection moulding

The tinning process protects wires from corrosion and increases the durability of soldered joints.

Assembly of bundles

Comprehensive assembly of electrical harnesses, ready for installation at the customer's premises.

Quality control

The tinning process protects wires from corrosion and increases the durability of soldered joints.

STARPOL electrical harnesses in various industries

Our harnesses are used in many industries – from automotive and transport, through household appliances, to construction and the engineering industry. We carry out both prototype series and large serial projects.

Automotive industry

electrical installations for passenger cars, lorries and buses.

Household appliances and electronics

wires and cables for household appliances and consumer electronics.

Industry and automation

wiring of machines and production lines.

Energy and telecommunications

dedicated bundles for power supply, data transmission and network infrastructure systems.

We work in accordance with the highest standards of quality and safety.

Starpol II Sp. z o.o. has for years focused on quality, safety, and production reliability. This is confirmed by the ISO certificates obtained as a result of independent audits conducted by reputable certification bodies. Thanks to them, our clients can be sure that all processes – from material purchasing, through the production of wiring harnesses and metal components, to the final inspection of finished products – are carried out in accordance with international standards.

quality management system

ISO 9001 is the most recognised quality management standard in the world. Its implementation at STARPOL enables continuous control of production processes, increased efficiency and product consistency, as well as improved customer satisfaction. This certificate confirms that every stage of our operations meets high quality requirements.

environmental management

Environmental awareness and responsibility for the natural environment are an important part of our strategy. Holding the ISO 14001:2015 certificate means that we conduct our business with respect for the environment – we minimise waste, manage energy rationally and implement solutions that limit the negative impact of production on the environment.

quality of welding processes

The welding processes carried out at STARPOL comply with the requirements of ISO 3834-2 and EN 15085-2 standards. These certificates confirm the highest quality, safety, and technical compliance of welded joints. As a result, our metal structures meet the requirements of domestic and international clients, including those in the industrial and transport sectors.

Quality control of electrical harnesses

Every wiring harness manufactured at Starpol undergoes certified quality control. We not only verify compliance with technical documentation, but also perform electrical tests, resistance measurements and detailed visual inspections. This gives our customers the assurance that the products they receive meet the highest standards of safety and reliability.

We follow procedures compliant with ISO 9001 and ISO 3834-2 standards, and the entire inspection process is documented and archived. This is particularly important for customers in the automotive and industrial sectors, where full repeatability and documented quality are required.

Do you require custom-made wiring harnesses?

We will take care of production.

Trust Starpol’s experience and modern machine park. We manufacture electrical harnesses in accordance with customer documentation – from cutting and braiding wires to final assembly and certified quality control. Contact us for a quick, tailored quote.