Plastic injection moulding – precision parts for harnesses

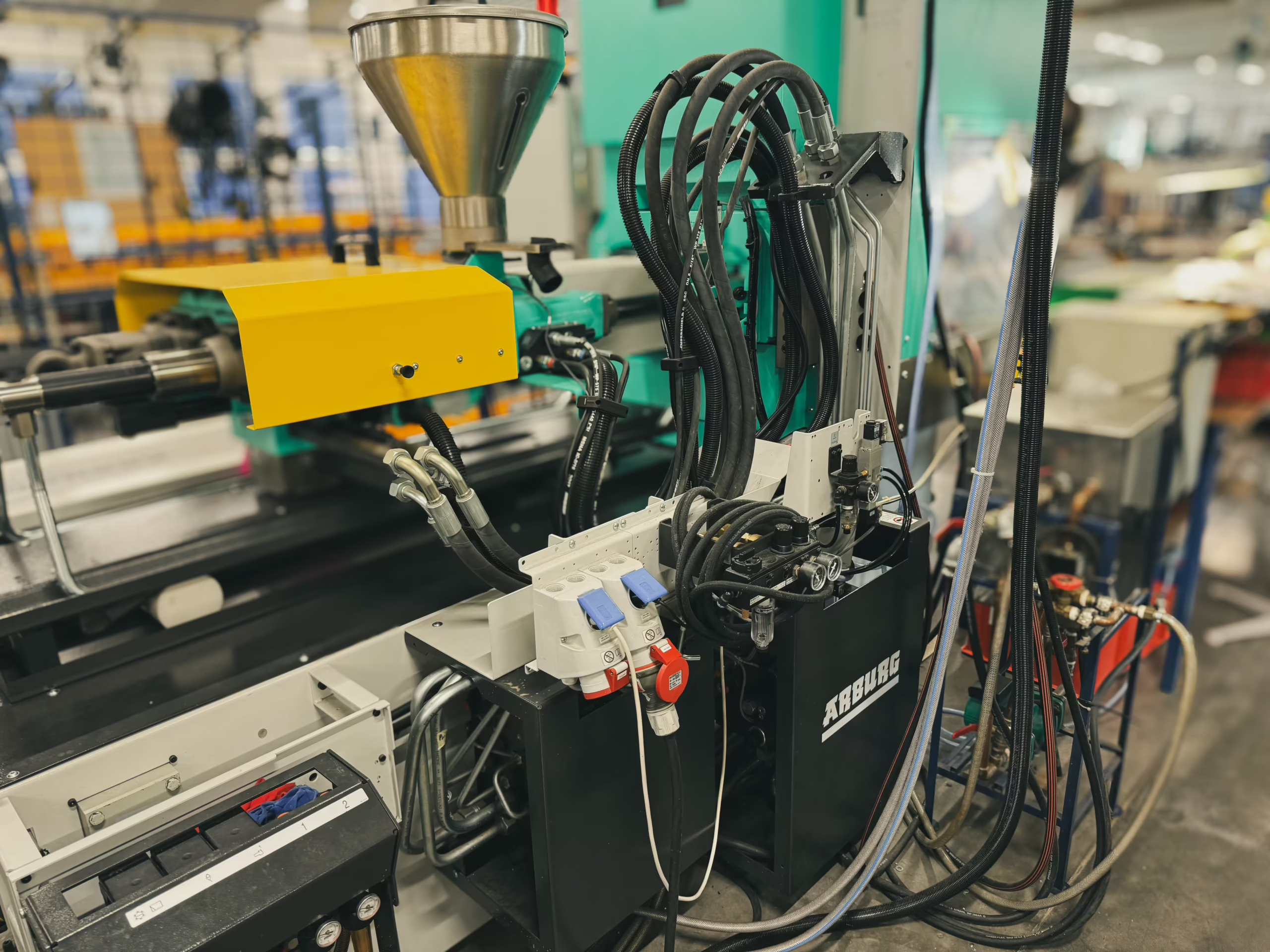

At Starpol, we offer injection moulding of plastic components used in wiring harnesses, such as covers, sleeves, holders and structural elements. Thanks to modern Arburg and Battenfeld machines, we create high-precision and durable parts tailored to the customer’s specific requirements.

How does the plastic injection process work at STARPOL?

Automation from start to finish

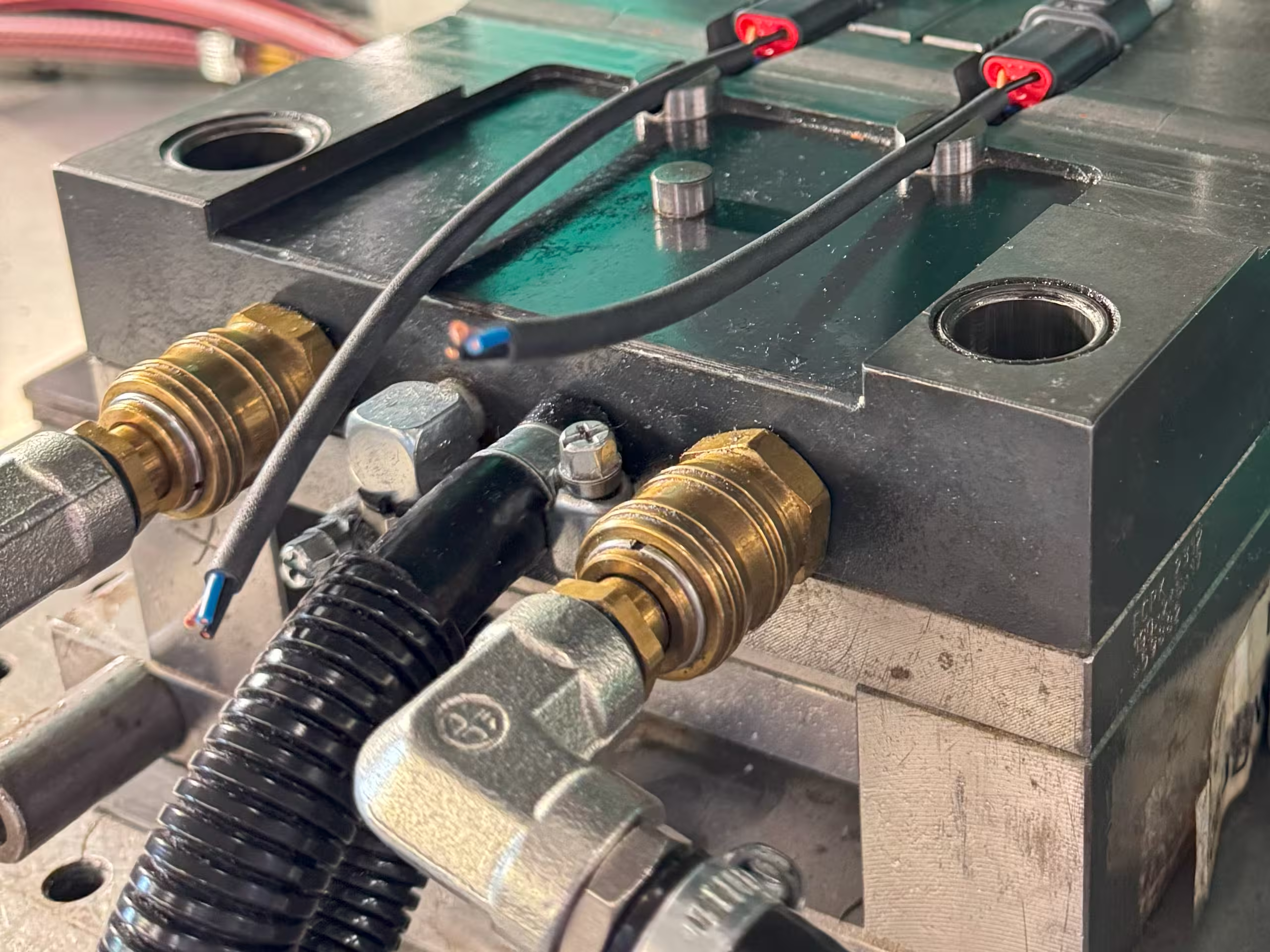

We begin the process with approved design documentation — a 3D model and material specifications. Next, we select the mould and material (engineering plastic, ABS, PA, etc.), and run injection cycles on Arburg (Allrounder 470C, 375V) or Battenfeld BA350V/050H machines, controlling the pressure, temperature and cooling time parameters. After injection, the parts are cooled, removed and subjected to quality control (dimensional and visual).

Our injection moulding machines and equipment

Arburg Allrounder 470C – horizontal injection moulding machine, ideal for larger and more complex parts

Arburg Allrounder 375V – vertical injection moulding machine, ideal for parts requiring assembly in the mould

Battenfeld BA350V/050H – high-performance machine for production series

Where is injection moulding effective?

Automotive industry

Cable covers and sockets in the automotive industry

Przemysł

Tuleje dystansowe, przekładki w urządzeniach przemysłowych

Electronics

Mounting brackets and clips in electronics

household appliances

Safety and insulation components in household appliances

What you gain thanks to

injection moulding at STARPOL?

production of complex parts in a single cycle

Plastic injection moulding allows you to obtain finished, complex components without the need for additional processing. This saves you time and production costs, while providing you with components that are fully compliant with the documentation.

Flexibility and rapid change of forms

Thanks to modern Arburg and Battenfeld injection moulding machines, we can quickly adapt the process to different moulds and materials. This enables us to produce both short prototype series and large serial orders.

Repeatability and consistent quality

Automation of the injection process and control of parameters (pressure, temperature, time) ensure perfect repeatability of details. Each product meets quality requirements and ISO 9001 standards, which guarantees reliability.

Application in automotive and industrial sectors

Our plastic components are widely used in the automotive, electronics, household appliances and industrial sectors. They ensure durability, resistance to external factors and a perfect fit for customer requirements.

How we provide this service

See the technological stages involved in this offer – from cable preparation to installation and testing.

Injection moulding

Injection moulding of components

Do you require customised plastic components?

Order plastic injection moulding at STARPOL

We design, injection mould and deliver plastic parts in accordance with customer documentation — quickly, precisely and with quality control.