Cutting, stripping and crimping wires

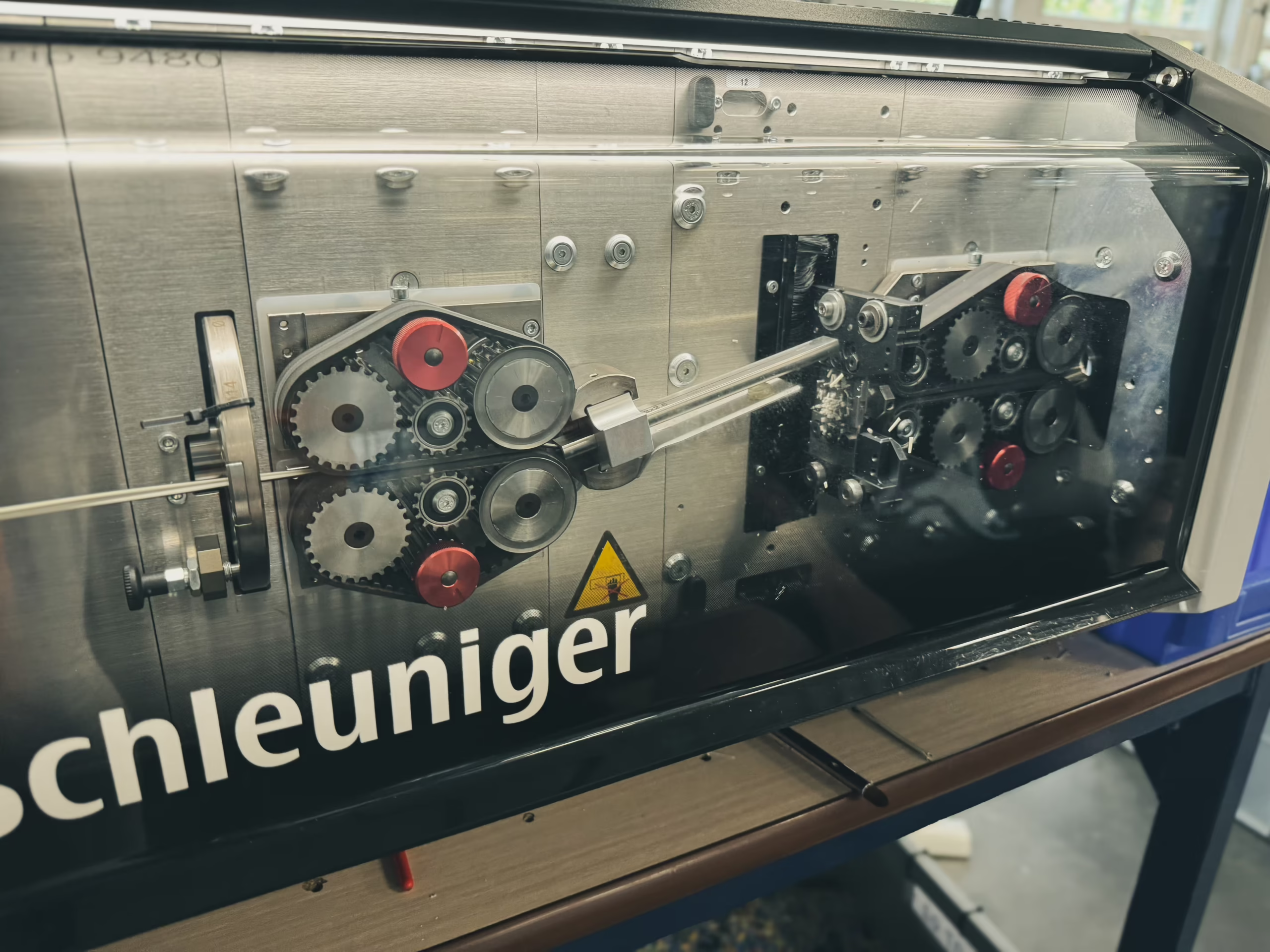

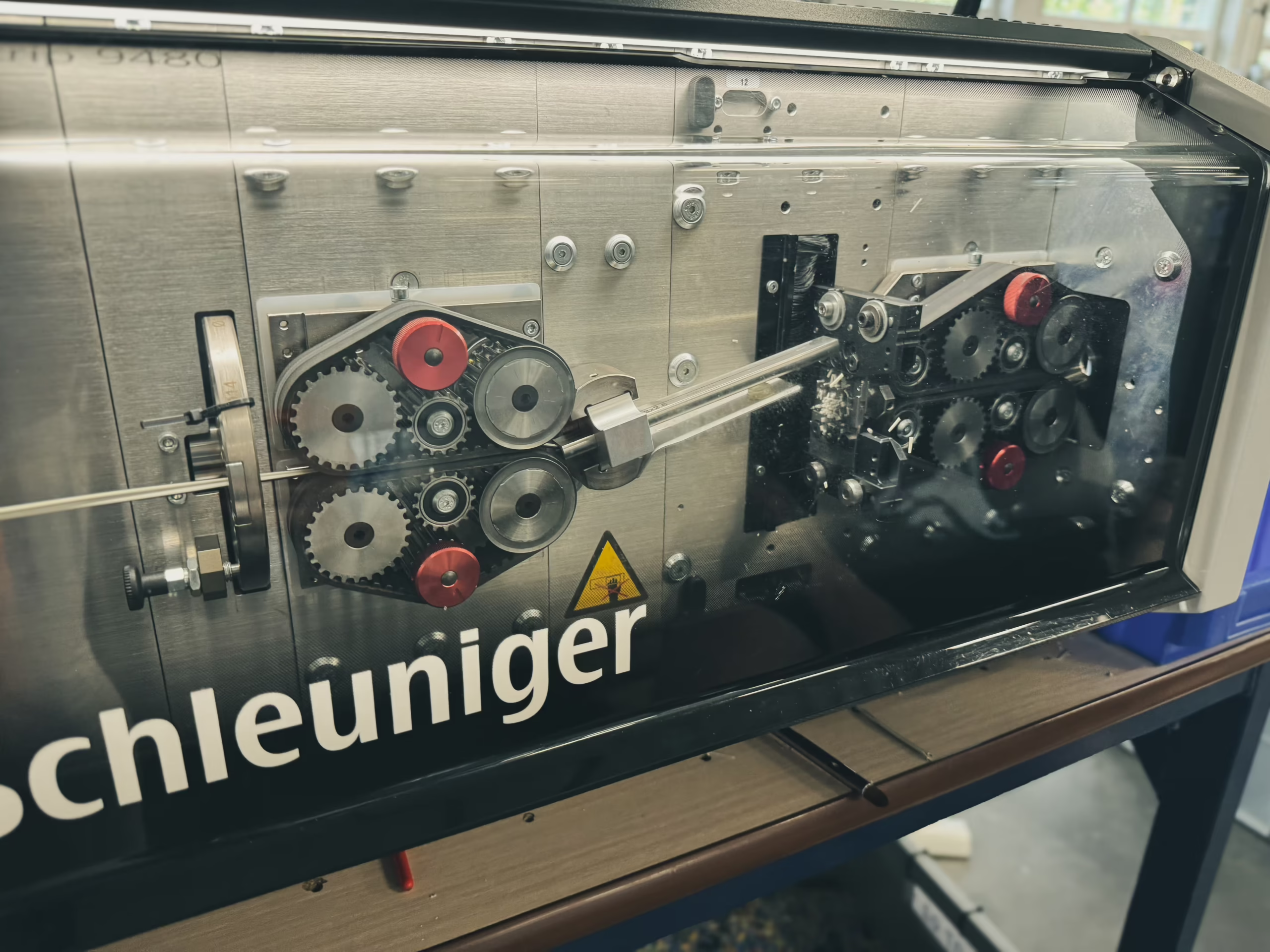

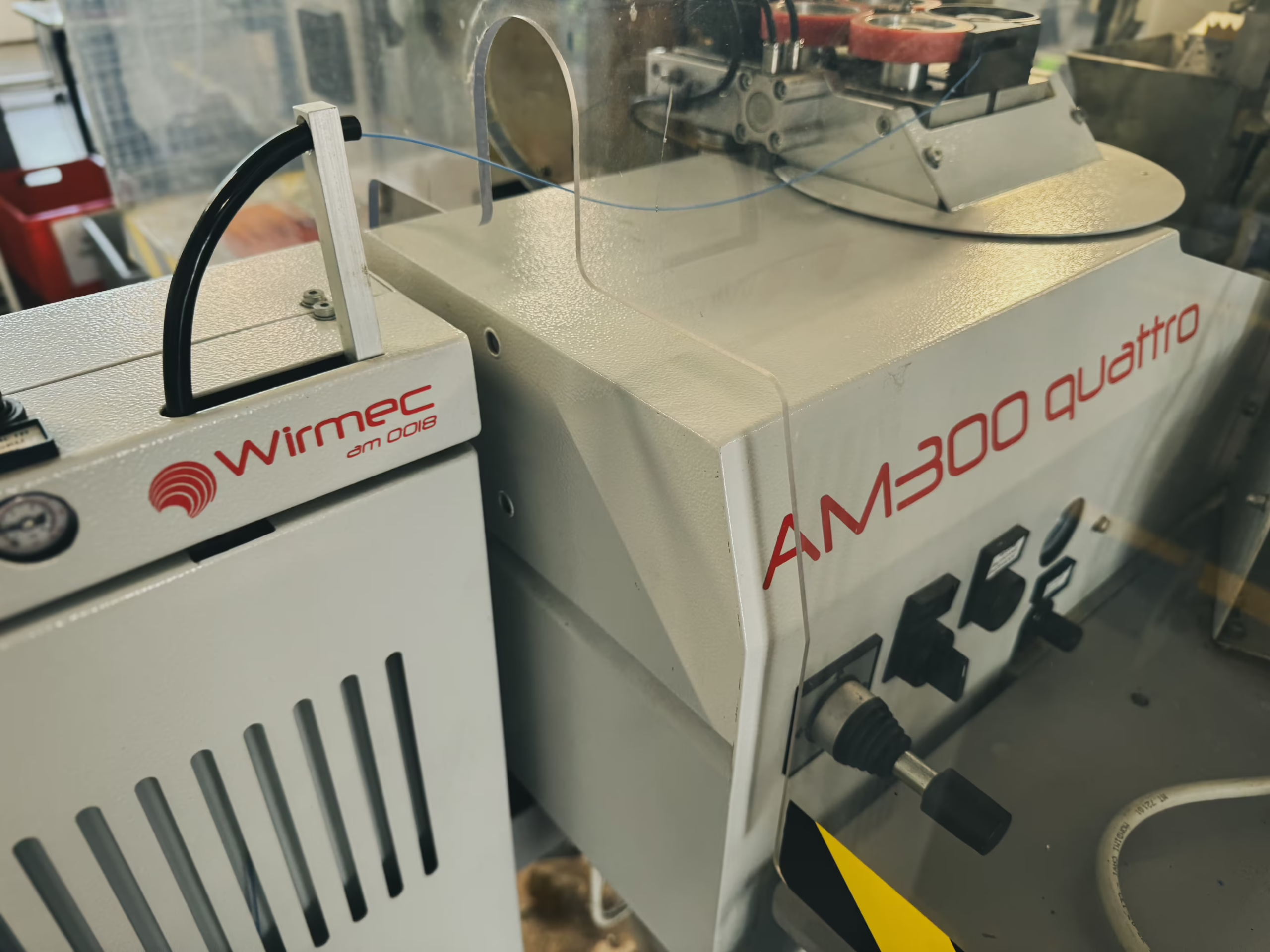

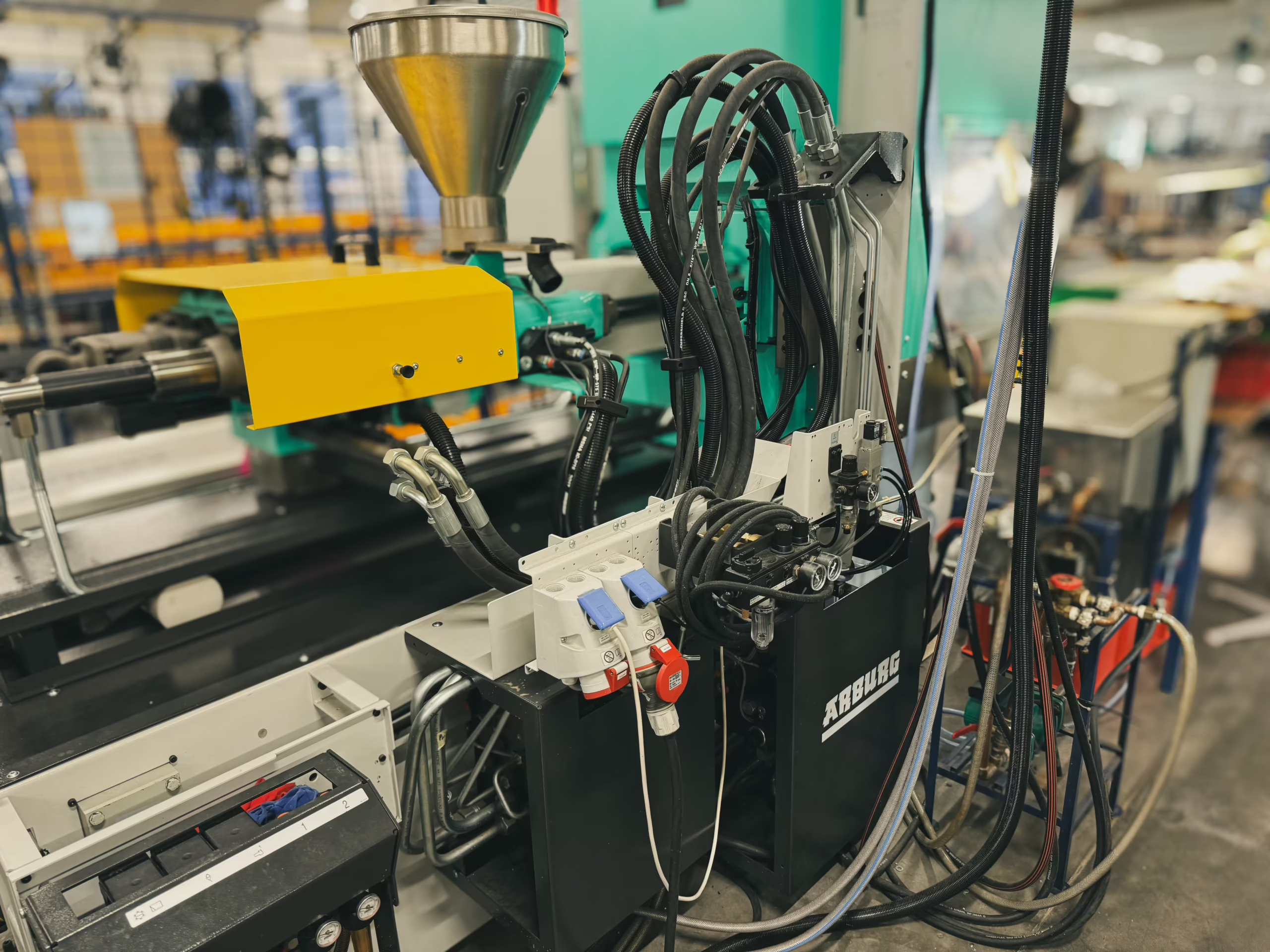

Automatic cutting, stripping and crimping of wires is the foundation of modern electrical harness production. Thanks to advanced Komax, Schleuniger and Wirmec machines, we carry out processes with the highest precision, ensuring repeatability and reliability in every series – from prototypes to large-scale production.

What does the process of cutting, stripping and crimping wires involve?

Automation from start to finish

The process begins with automatic cutting of wires to a precisely specified length. Next, the ends are stripped with high accuracy, which enables further crimping of the ends and assembly of connectors. Thanks to full automation, we eliminate human error and ensure perfect repeatability of details.

Precision and quality for every industry

Zaawansowane maszyny Komax, Schleuniger i Wirmec pozwalają obsługiwać szeroki zakres przekrojów i typów przewodów. Proces cięcia i zakuwania spełnia rygorystyczne wymagania jakościowe branży motoryzacyjnej, AGD, przemysłowej i elektronicznej.

How we provide this service

See the technological stages involved in this offer – from cable preparation to installation and testing.

Cutting and processing of cables

Cutting The process of cutting and processing pipes and processing pipes

Multi-wire machines

Obróbka kabli wielożyłowych/taśm

Maszyny Crimp Center

Linie Crimp Center – cut & strip, crimp, seal

from prototype to series production

Production flexibility

Our machine park enables us to carry out both short prototype series and large serial projects. This allows us to tailor production to individual customer needs, regardless of the scale of the order.

Why should you entrust us with the preparation of cables?

Do you require ready-made cables?

Trust STARPOL's experience

Please contact us to discuss the details of our cooperation and obtain an individual quote.