Production of metal components

We manufacture metal components in accordance with customer documentation, using modern technologies such as laser cutting, TIG/MAG welding and CNC machining. Our products are manufactured with attention to precision, durability and repeatability, and all processes are subject to certified quality control.

Our main processes

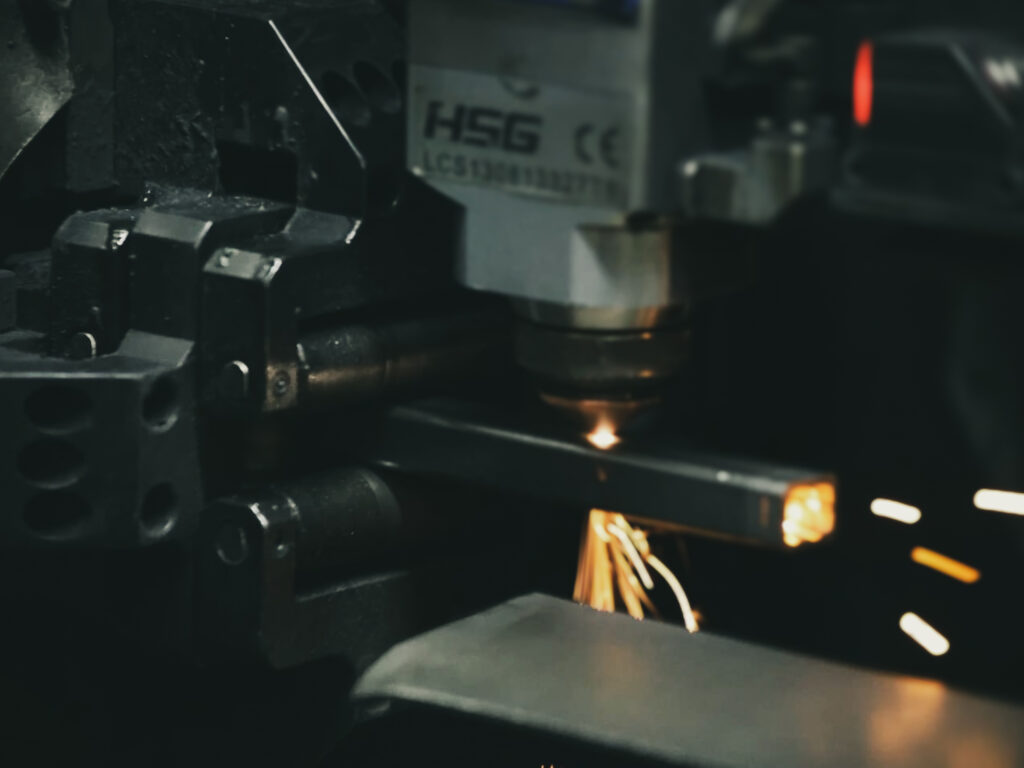

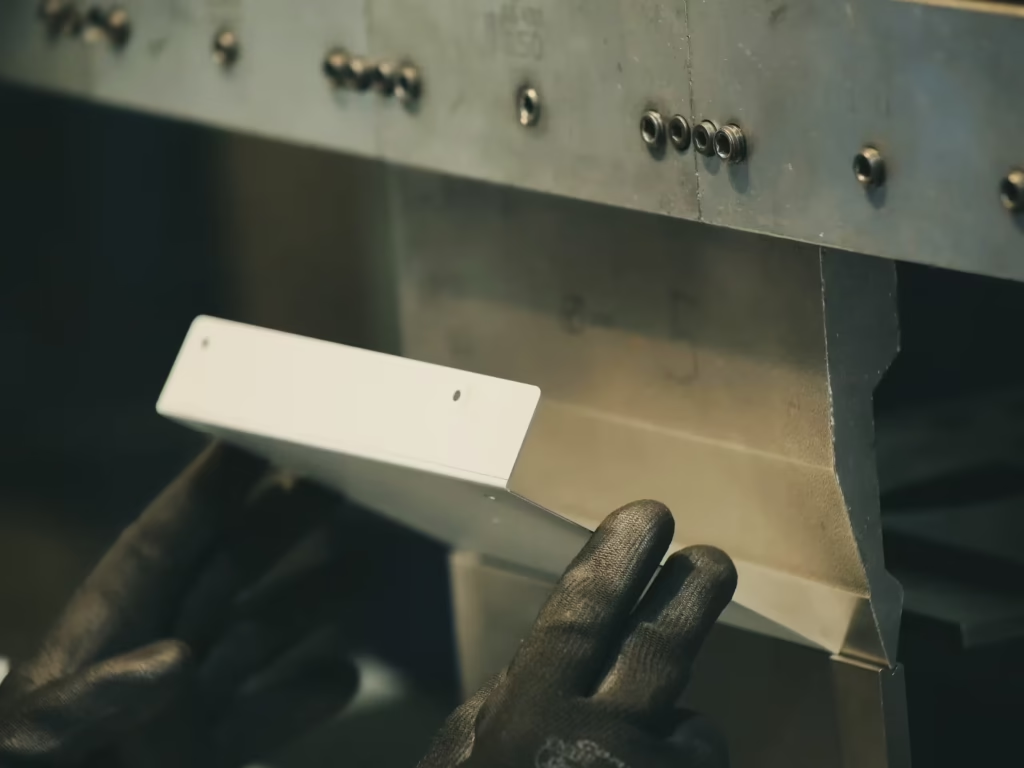

Laser cutting

Precise cutting of details in sheets and profiles with the highest accuracy.

TIG/MAG welding

Manual and robotic welding using TIG and MAG methods ensuring durable welds.

CNC machining

Advanced machining in CNC centres, guaranteeing repeatability and compliance with documentation.

Metal component machining processes

At Starpol, we carry out comprehensive production of metal components in accordance with customer documentation. Our capabilities include laser cutting of sheet metal, pipes and profiles, surface treatment, bending, stamping, rolling, as well as CNC machining, welding, annealing and assembly. Thanks to modern machines and certified quality control procedures, we ensure the highest repeatability and dimensional accuracy. We also offer anti-corrosion coating in cooperation with certified partners. In the absence of documentation, our engineers use reverse engineering to recreate details and start production. This makes Starpol a partner you can trust with both short runs and large serial projects.

Laser cutting of pipes and profiles

Cutting locks and holes in pipes and profiles reduces welding and facilitates assembly. Performed on an HSG TM-65 laser with a 6500 mm magazine.

The materials we work with

We manufacture components from various types of steel and non-ferrous metals. Thanks to modern machinery and quality control, we can carry out projects that require precision and high repeatability.

Black steel

Cutting sheet metal up to 20 mm thick, structural and technical components.

Stainless steel

Processing of sheet metal and profiles up to 12 mm thick, high corrosion resistance.

Aluminium

Lightweight and durable components, precision machining up to 8 mm thick.

Copper and brass

Cutting and processing pipes, profiles and sheets – excellent conductivity and aesthetics.

Prototypes and reverse engineering

Thanks to 3D scanning technology, we recreate missing documentation and create digital models of details. On this basis, we develop complete technical documentation and launch the production of prototypes and spare parts. Reverse engineering at Starpol is a fast and precise solution for customers who need faithfully reproduced components.

Starpol metal components in various industries

Our components are used in many industries, from automotive and transport, through household appliances, to construction and engineering. We carry out both prototype series and large serial projects.

Automotive industry

We manufacture structural components, brackets and holders used in the automotive industry.

Machinery industry

Precision parts and components for industrial machinery and specialised equipment.

Household appliances and electronics

Housings, handles, mounting elements and technical details for household appliance manufacturers.

Transport and structures

Welded and cut components for trucks, semi-trailers and steel structures.

We work in accordance with the highest standards of quality and safety.

Starpol II Sp. z o.o. has for years focused on quality, safety, and production reliability. This is confirmed by the ISO certificates obtained as a result of independent audits conducted by reputable certification bodies. Thanks to them, our clients can be sure that all processes – from material purchasing, through the production of wiring harnesses and metal components, to the final inspection of finished products – are carried out in accordance with international standards.

quality management system

ISO 9001 is the most recognised quality management standard in the world. Its implementation at STARPOL enables continuous control of production processes, increased efficiency and product consistency, as well as improved customer satisfaction. This certificate confirms that every stage of our operations meets high quality requirements.

environmental management

Environmental awareness and responsibility for the natural environment are an important part of our strategy. Holding the ISO 14001:2015 certificate means that we conduct our business with respect for the environment – we minimise waste, manage energy rationally and implement solutions that limit the negative impact of production on the environment.

quality of welding processes

The welding processes carried out at STARPOL comply with the requirements of ISO 3834-2 and EN 15085-2 standards. These certificates confirm the highest quality, safety, and technical compliance of welded joints. As a result, our metal structures meet the requirements of domestic and international clients, including those in the industrial and transport sectors.

Do you have documentation for the metal components?

We will take care of production.

From laser cutting and CNC machining, through welding and assembly, to anti-corrosion coatings – at Starpol, we carry out comprehensive production in accordance with your requirements.